- Design intent

- Engineering critical values

- Optimized parameters

- Compliance with performance

- Validation analyses

Creo, the shorthand name for Creo Parametric, (formerly known as Pro Engineer) is a powerful and intuitive 3D CAD software optimized to address the challenges organizations face as they design, analyze, and share information with downstream partners.

Developed by PTC, the original pioneers of parametric CAD, Creo is a powerful foundational software supporting an integrated family of product design tools used by thousands of manufacturers worldwide.

The Creo family of design applications, modules, and extension speak a common language, meet the needs of different stakeholders, and truly combine parametric and direct modeling techniques. Creo helps build bridges instead of barriers between you, your ideas, your teammates, your partners, and your customers.

Creo Parametric 3D CAD software can easily be customized and extended through the addition of modules and extensions, but the product family also contains stand-alone purpose build design applications such as Creo Simulate, Creo Direct, Creo Layout & Creo Options Modeler. Each stand-alone app serves a different purpose in the product development process.

From concept to design to analysis, to effectively sharing your information with downstream partners (such as manufacturing and technical publications), Creo is a rock-solid foundation for any design group. It supports the needs of modern manufacturing and product development organizations.

What makes Creo Parametric such a powerful product design and development tool in your company’s quest for a competitive advantage?

There are many unique aspects of the innovative Creo product family – Here are my top 4.

Flexibility

For designers who are involved in multiple phases of the product development process, PTC Creo provides scalable access to the right capabilities. Subscription licensing enables to adjust and right-size their software over time.

For those involved in specific aspects of the product development process, there are apps tailored to meet individual needs. Regardless of your role in the product development process, you can use the right tool at the right time.

Interoperability

All of the products in the PTC Creo family speak the same language. Because of this common language, your data flows seamlessly between different apps. This means no more recreating work as you move through the design process and no more walls to throw your data over.

Combined benefits of both parametric and direct modeling

PTC Creo integrates the power of both 3D CAD modeling approaches into a single system, so you get the power and control of parametric modeling combined with the speed and flexibility that’s only available through direct modeling.

Multi-cad Data Handling

PTC Creo includes an incredible convince ability to work with and edit data from any CAD source. This means no recreating designs because of incompatible data, and no need to ask your partners or customers to change CAD software systems.

Want to learn more about what PTC Creo Parametric 3d CAD software can do for you? Download the Creo Parametric Datasheet or contact us to talk with a technology specialist today!

On November 20, 2018, PTC announced the ~$70M acquisition of an advanced generative design software company named Frustum Inc. Frustum’s technology leverages artificial intelligence (AI) to generate design options in a process called “generative design.” It will be worth your time to follow this acquisition and how PTC incorporates the technology into their flagship offerings. It should be a transformative addition to PTC’s Creo portfolio.

Frustum offers patented desktop and cloud-based engineering software from their headquarters in Boulder, CO. Their software enables engineers and designers to go beyond the limits of their personal experience by leveraging powerful AI capabilities that guide the discovery of high-performance, next-generation product designs.

When asked about the acquisition, Jim Heppelmann, President and CEO of PTC said “PTC is pushing the boundaries of innovation with this acquisition…Creo is core to PTC’s overall strategy, and the embedded capabilities from ANSYS and, later, Frustum will elevate Creo to a leading position in the world of design and simulation. With breakthrough new technologies such as AR/VR, high-performance computing, IoT, AI, and additive manufacturing entering the picture, the CAD industry is going through a renaissance period, and PTC is committed to leading the way.”

Earlier this year PTC announced a strategic relationship with ANSYS. Frustum complements this relationship and will help bring analysis upstream to the very start of the design process. With embedded Frustum and ANSYS capabilities, Creo will be able to recommend design approaches using generative design, guide the user through the iterative design process using ANSYS Discovery Live, and ultimately validate the full product design at scale using the broader ANSYS Discovery suite. With these capabilities embedded in Creo, engineers will have unmatched capabilities to rapidly drive product innovation.

Here is some more information about the acquisition from the official PTC press release…

“This acquisition is a natural step for PTC and its customers,” said Jeff Hojlo, program director, product innovation, IDC. “AI and machine learning (ML) are widely discussed as two of the most impactful technologies of the future. For design, engineering, and R&D, the potential positive impacts of complementing the development process with AI and ML are astounding: lowering cost of quality (which is currently 20-25 percent of annual revenue at the average manufacturer), improving product success rate (which remains very low with more than 80 percent of products failing), and improving time to market and time to revenue by meeting customer needs accurately the first time.”

The Power of Generative Design

With generative design, engineers can interactively specify the functional requirements and goals of their design, including preferred materials and manufacturing processes—and even indicate key design parameters that take into consideration purchasing decisions, manufacturing capacity, supply chain status, and regional-required product variances. The system then uses AI and powerful high-performance computing techniques to present design alternatives for consideration as a starting point or as a final solution. By removing the constraints of human imagination and experience, engineers will be able to interact with the technology to create superior designs and innovative products more quickly.

Generative design is appealing to PTC’s vast customer base as they seek ways to:

- Increase engineering productivity

- Improve innovation and conceptual design exploration

- Develop higher-performance designs that are lighter weight, with improved durability

- Optimize new products for improved manufacturability, reduce material costs, and decrease manufacturing cycle times

- Create complex geometries optimized for additive manufacturing

- Deliver better products faster

The Impact of Artificial Intelligence

Integral to Frustum’s technology is a powerful AI component that learns, evolves, and, ultimately, performs key tasks, including:

- Providing valuable feedback to a designer early in the design phase

- Optimizing designs for multiple objectives simultaneously and offering a designer with multiple novel design alternatives, which enables companies to substantially reduce engineering cycles

- Modifying designs to manage multiple requirements and constraints, physics, materials availability, manufacturing processes, and design objectives

- Automating testing the outcomes of the design with other enterprise insights, including costing, supply chain, and quality data

The Transaction

The transaction closed on Monday, Nov.19, 2018. The acquisition is not expected to add material revenue for 2019 or to be dilutive to the financial guidance PTC provided on Oct. 24, 2018.

Additional Resources

Forward-Looking Statements

This news release contains statements about future events, including business performance and the effect of the acquisition on our future financial results, the integration and development of solutions, and the expected value of the acquired technology to users. These statements are “forward-looking statements” and actual results may differ materially from those projected as a result of certain risks and uncertainties, including that the acquisition may not have the expected effect on future financial results and that the integration of the solutions may not occur when or as expected, and those risks and uncertainties described in PTC’s filings with U.S. Securities and Exchange Commission. These forward-looking statements reflect our beliefs as of the date of this release and we undertake no obligation to update or revise any forward-looking statement, whether as a result of new information, future events or otherwise.

We’re all challenged to get as much work as possible done within limited timeframes. One of the easiest ways for engineers and designers to get more done is by re-using design knowledge. I understand the obstacles between reuse. It can be difficult to capture and re-use engineering and design knowledge when captured on whiteboards, notebooks, and napkins. The ideal process takes advantage of effective and efficient knowledge capture using tools digital like Mathcad to communicate:

When engineers are not using the right applications that they need to do their job, then mistakes can happen. Steps get missed. Products don’t get designed the way they need to. Finding the best math software for your product designs can be difficult.

We can help you build your products better and eliminate errors by giving you a better solution to engineering calculations. With PTC’s engineering calculations software, Mathcad, you can manage your intentions, capture your thoughts, and share it with others.

PTC Mathcad enables enterprises to:

- Prevent loss of intellectual property captured in uncontrolled paper form

- Improve ability to digitally capture and share knowledge

- Optimize critical design and engineering processes

- Speed up time to market

- Improve compliance with regulations

PTC Mathcad allows engineers to quickly and easily:

- Solve, document, share and reuse vital calculations

- Combine text, math, graphs, and images in a single worksheet

- Enable knowledge capture, data reuse, and design verification

Why is PTC Mathcad the best math software? It’s:

Intuitive

– Easy-to-use, whiteboard interface

– Natural math notation

Comprehensive

-Combines live math, text, graphics, and programs in a single readable form

-Powerful numeric and symbolic math

-Manages units automatically

Self-Documenting

-Traceable, readable form

-Knowledge capture, verification, and re-use

Document-Centric

-Complex, professional engineering design documents

-Intuitive, quick, easy

User-Friendly

-Usable, learnable interface

-Explore complex engineering calculations in a familiar environment

Advanced Technology

-Display, manipulate, analyze, and plot 2D and 3D data

-Full unit support

-Access hundreds of built-in functions or create your own

PTC Mathcad allows you to automatically calculate, capture, and communicate design intent and critical calculations. This math software gives you the ability to standardize engineering methods, approaches, and workflows. Eliminate mistakes by performing validation and verification throughout the design process and dramatically lower calculation errors.

Price of Mathcad

Get PTC Mathcad, the best math software, at an affordable price: Check out the latest prices on our Mathcad webpage.

Contact us if you would like to purchase a seat of Mathcad or download the free trial today.

PTC Mathcad is an engineering calculations software that allows you to perform, analyze, document, and share calculations easily. To put it simply – Mathcad Express is a free version of Mathcad Prime with lifetime limited functionalities.

When you download PTC Mathcad Express, you are able to access full capabilities that you would with the licensed version of PTC Mathcad Prime 6.0 for the first 30 days. At the end of 30 days, you’ll lose the advanced math notations but will still have lifetime access to PTC Mathcad Express.

PTC Mathcad Capabilities

*Available for the first 30 days in Mathcad Express

| Express | Subscription | |

| PTC Mathcad Express | Individual/Multiple Licenses | |

| New in Prime 6.0 | ||

| Spell Check* | * | X |

| Hyperlinks in Text* | * | X |

| Custom Margin, Header, Footer Sizes* | * | X |

| Usability | ||

| Write Equations using Natural Math Notation | X | X |

| Basic Math | ||

| Automatic update of calculations | X | X |

| Algebra and trigonometry operators and functions | X | X |

| Documentation | ||

| Comprehensive documentation | X | X |

| Standardize engineering process using templates* | * | X |

| Content Protection* | * | X |

| Equation Wrapping* | * | X |

| Plotting | ||

| X-Y Plots | X | X |

| Advanced plot types: Polar, Contour, 3D* | * | X |

| Advanced Math | ||

| Programming* | * | X |

| Solve systems of linear, non-linear, and differential equations | – | X |

| Evaluate expressions symbolically* | * | X |

| Embed Excel directly in your worksheet* | * | X |

| Advanced Engineering Mathematics: e.g. Design of Experiments, Differential Equations, Solving Regression* | * | X |

| Advanced Numeric Functions: e.g. Fourier Transforms, Signal Processing, Statistics & Data Analysis* | * | X |

| License Options | ||

| Centralized IT management and administration | – | X |

| eLearning Libraries | – | X |

PTC Mathcad Express includes:

- Natural math notation

- Automatic update of calculations

- Algebra and trigonometry operators and functions

- Comprehensive documentation (integrating live math, text, plots, and images in one spot)

- X-Y Plotting

- Automatic unit checking and conversion

- Basic numeric functions and operators

Mathcad Premium (licensed version of Mathcad) includes:

- Spellcheck, hyperlinks, and customized margins, headers, footers

- Excel component (integration with Microsoft Excel spreadsheets)

- Content protection (protect content with passwords, locking, and degree of access)

- Solving and optimization

- Programming (customizing your environment to meet your specific requirements)

- Templates (simply use templates as a basis for your new worksheets)

- Advanced plotting

- Symbolics engine (analytics/theoretical approach to math)

- Export to Microsoft Word (ability to save as word document file)

- Advanced math functions (perform linear algebra, non-linear algebra, or matrix manipulations)

Mathcad Free Trial

Download PTC Mathcad Express for a 30 day trial of what you can expect from a fully licensed version of PTC MC Prime 6.0 and when you’re ready to purchase a license, contact us.

FAQ

Can a Mathcad Prime file be opened in Mathcad Express?

Mathcad worksheets that are created with the fully licensed version of Mathcad Prime can be opened in Mathcad Express. In MC Express, edits can be made to the text. In MC Express, any edits made to the math that utilizes a premium feature will issue a message to the user indicating that the feature requires a license. Math created with premium features will not calculate in MC Express. Accordingly, math created with Express/non-premium features will in-fact recalculate in MC Express.

Looking to make some major advances in innovation and digital transformation at your company? Check out how PTC Creo is the leading 3D CAD software in the industry.

I’ll start off explaining to you what exactly PTC Creo Parametric is and what it does for your design process.

What is PTC Creo Parametric?

PTC developed a premium parametric and direct computer-aided design (CAD) modeling software called Pro/ENGINEER. Pro/E was rebranded into PTC Creo Parametric and is now the leading product design software in the product development industry. Over 12,000 manufacturing companies worldwide use PTC Creo (Pro/E) software.

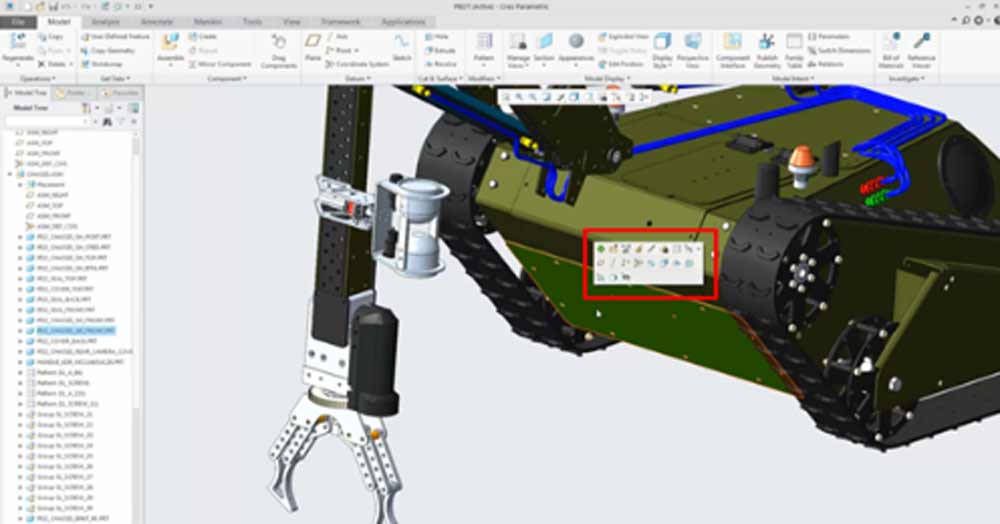

PTC Creo software gives you the ability to work with and edit data from almost any CAD source without recreating designs due to incompatible data. Creo provides a robust and scalable 3D CAD product design toolset for all different skill-levels of engineers and designers. With Creo CAD software you can quickly create 3D models of any part or assembly and improve existing designs with comprehensive surfacing capabilities.

PTC Creo Parametric provides 3D capabilities such as:

- 3D Part & Assembly Design

- Automatic 2D Drawing Creation

- Parametric & Freestyle Surfacing

- Assembly Management & Performance

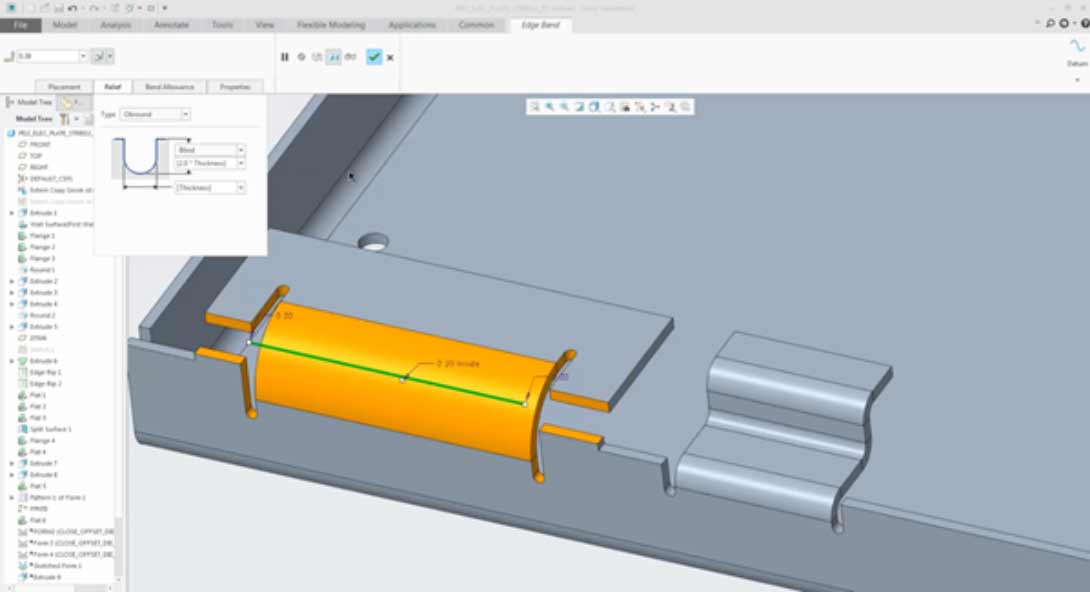

- Sheet Metal Design

- Mechanism Design

- Plastic Part Design

- Direct Modeling (Flexible Modeling)

- Additive & Subtractive Manufacturing

- Augmented Reality

- Multi-CAD

- Collaboration

- Piping & Cabling

- Rendering

- Design Exploration

- Fastener Design

- Advanced Framework Design

- Legacy Data Migration

- Human Factors Design

- Core Simulation Capabilities

How to Download PTC Creo

“I’m already using another CAD software. How do I know PTC Creo is right for me?” Chances are you like to ride the bike before you buy it, right? That’s why PTC allows you to try it out before you decide to purchase. Download a free 30-day trial of PTC Creo here.

PTC Creo Parametric Software is constantly improving

Every version of Creo is better than the last! For instance, when Creo 4.0 was released it included capabilities for additive manufacturing, model-based definition (MBD), and smart connected design that allows engineers to leverage 3D modeling to define individual components and product assemblies. With Creo 5.0 building on the previous release, it contains all of Creo 4.0’s functionality and more!

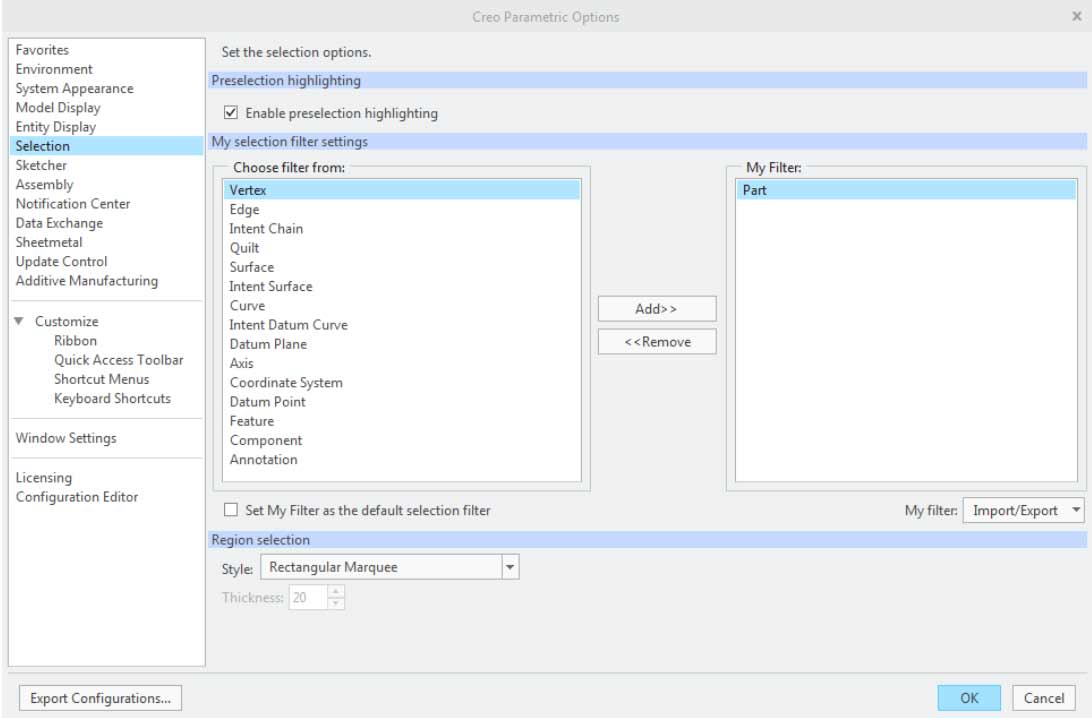

The Intelligent Mini Toolbar: the mini-toolbar gives you access to relevant options while staying focused on the graphics area.

Customizable Menus: you can now tailor the tool for optimal productivity to customize your own workflow.

Flexible Modeling for Sheet Metal: you can now edit sheet metal bends, bend reliefs, corner reliefs, corner seams, and forms – simplifying designs for faster analysis.

Enhancements to Geometry Manipulation: accessibility to side 2 directly from graphics window when you right-click on a feature without navigating to the dashboard each time; the extrude and revolve tools allow you to specify negative direction values to invert materials for offset geometry; extrude is added to offset to eliminate the step of creating intermediate construction features.

PTC Creo 5.0 includes Topology Optimization, Additive/Subtractive Manufacturing for metal 3D printing, Mold Machining, Flow Analysis, Multi-CAD Collaboration, and improved enhancements with geometry sketch regions, subdivisional modeling, surfacing, sheet metal tools, and volume helical sweeps.

Read more about the newest release in our blog called, “What’s New in Creo 5.0?” or download the data sheet here.

Creo Software – Technology of the Future

When you purchase PTC Creo Software, you have the power to publish, share, and create augmented reality experiences right inside of your 3D CAD models. This allows you to add value to your customer experience because they can now visualize your design with AR.

With Creo Parametric, you also have the power of simulating digital twins within your CAD models to collect real-time data from sensors on a physical product. You can reduce downtime while using this data to find performance issues and schedule predictive maintenance.

As the physical and digital worlds converge, digital transformation starting with the right CAD software is more relevant than ever. PTC Creo software eliminates barriers to innovation and is a solution for product development challenges.

Download a free 30-day trial of PTC Creo to see for yourself how the right CAD software gives you the tools you need to design above and beyond anything you’ve ever imagined.

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

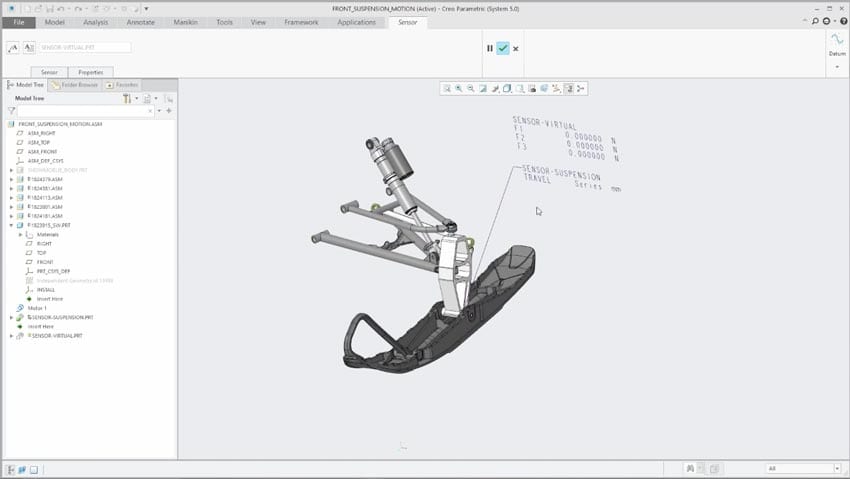

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

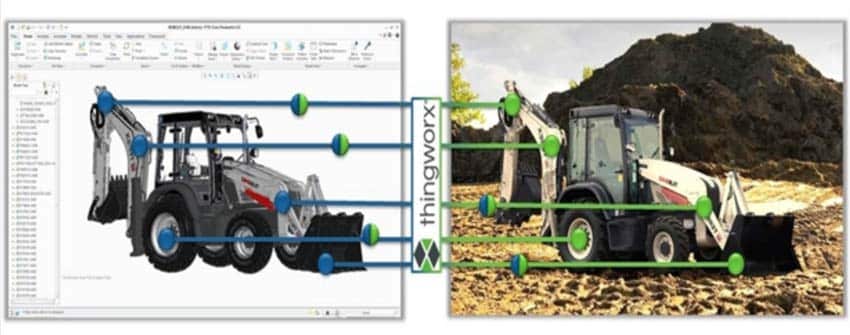

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

- Reuse and instrument released designs

- Embed sensors into new designs

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.