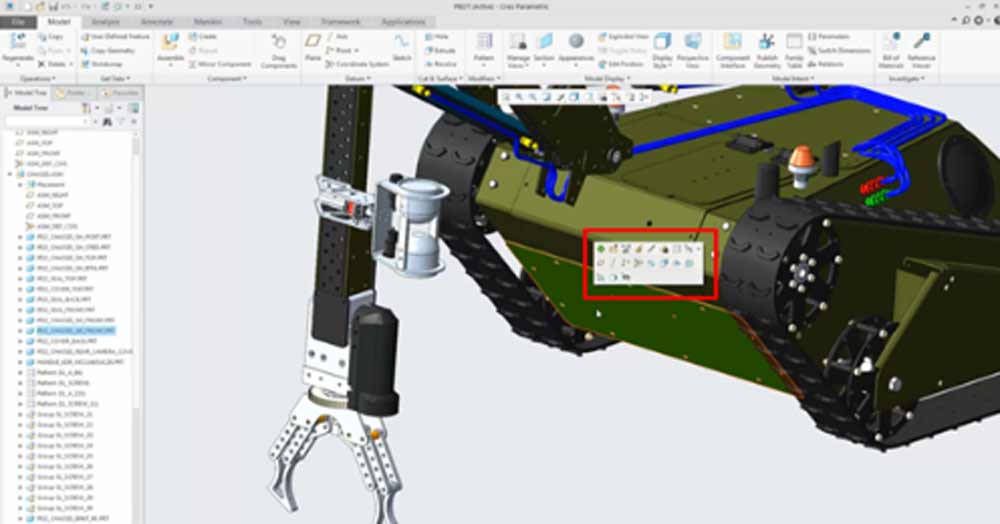

- 3D Part & Assembly Design

- Automatic 2D Drawing Creation

- Parametric & Freestyle Surfacing

- Assembly Management & Performance

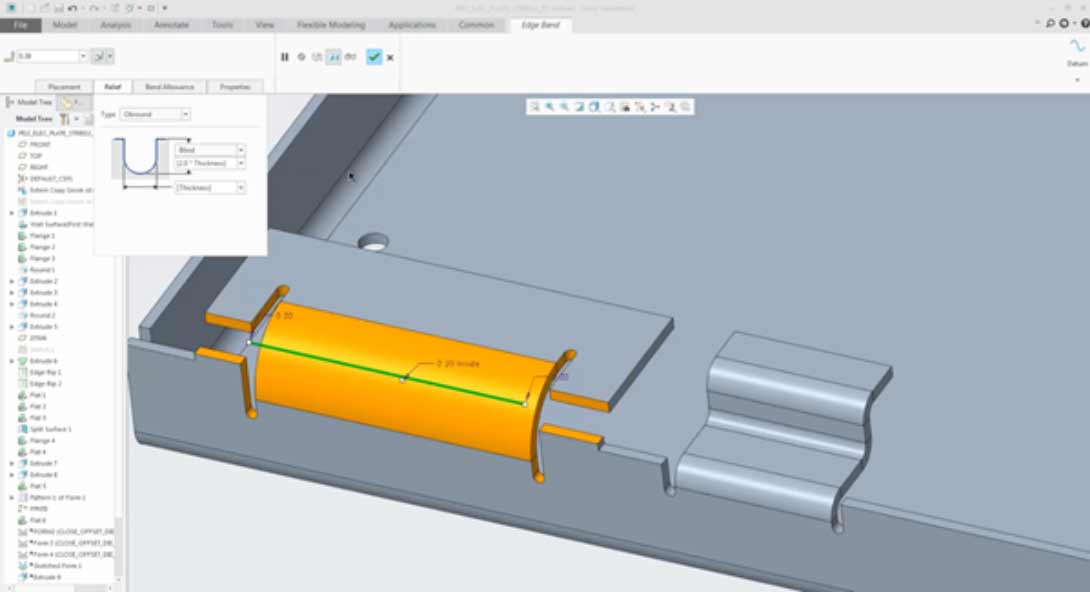

- Sheet Metal Design

- Mechanism Design

- Plastic Part Design

- Direct Modeling (Flexible Modeling)

- Additive & Subtractive Manufacturing

- Augmented Reality

- Multi-CAD

- Collaboration

- Piping & Cabling

- Rendering

- Design Exploration

- Fastener Design

- Advanced Framework Design

- Legacy Data Migration

- Human Factors Design

- Core Simulation Capabilities

Looking to make some major advances in innovation and digital transformation at your company? Check out how PTC Creo is the leading 3D CAD software in the industry.

I’ll start off explaining to you what exactly PTC Creo Parametric is and what it does for your design process.

What is PTC Creo Parametric?

PTC developed a premium parametric and direct computer-aided design (CAD) modeling software called Pro/ENGINEER. Pro/E was rebranded into PTC Creo Parametric and is now the leading product design software in the product development industry. Over 12,000 manufacturing companies worldwide use PTC Creo (Pro/E) software.

PTC Creo software gives you the ability to work with and edit data from almost any CAD source without recreating designs due to incompatible data. Creo provides a robust and scalable 3D CAD product design toolset for all different skill-levels of engineers and designers. With Creo CAD software you can quickly create 3D models of any part or assembly and improve existing designs with comprehensive surfacing capabilities.

PTC Creo Parametric provides 3D capabilities such as:

How to Download PTC Creo

“I’m already using another CAD software. How do I know PTC Creo is right for me?” Chances are you like to ride the bike before you buy it, right? That’s why PTC allows you to try it out before you decide to purchase. Download a free 30-day trial of PTC Creo here.

PTC Creo Parametric Software is constantly improving

Every version of Creo is better than the last! For instance, when Creo 4.0 was released it included capabilities for additive manufacturing, model-based definition (MBD), and smart connected design that allows engineers to leverage 3D modeling to define individual components and product assemblies. With Creo 5.0 building on the previous release, it contains all of Creo 4.0’s functionality and more!

The Intelligent Mini Toolbar: the mini-toolbar gives you access to relevant options while staying focused on the graphics area.

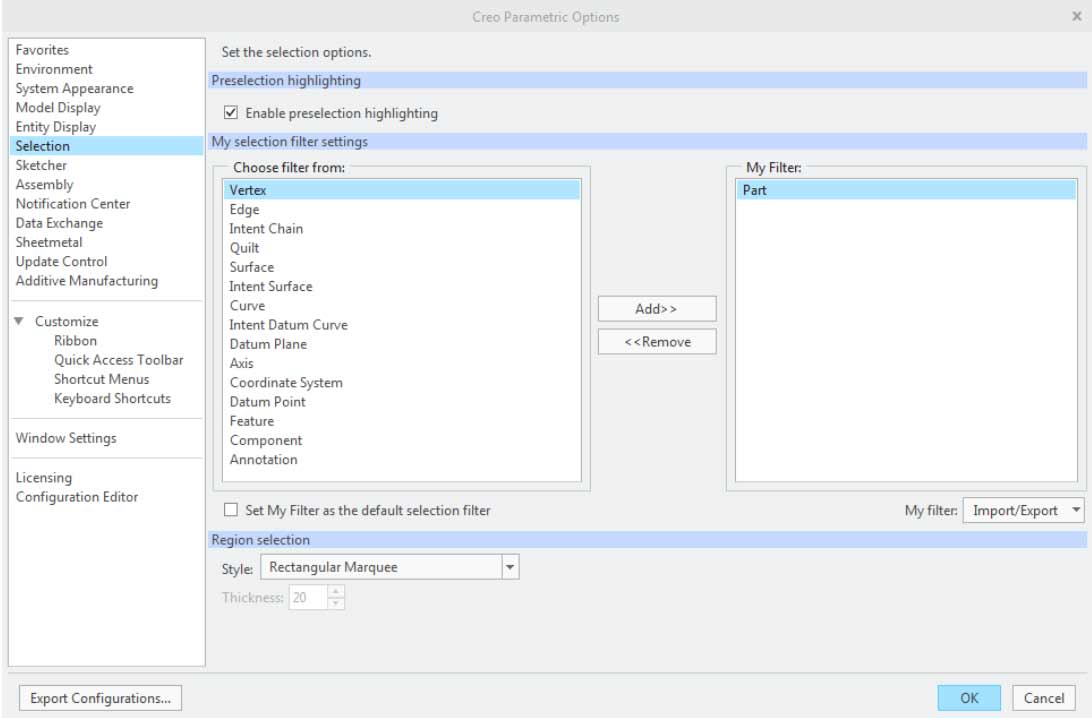

Customizable Menus: you can now tailor the tool for optimal productivity to customize your own workflow.

Flexible Modeling for Sheet Metal: you can now edit sheet metal bends, bend reliefs, corner reliefs, corner seams, and forms – simplifying designs for faster analysis.

Enhancements to Geometry Manipulation: accessibility to side 2 directly from graphics window when you right-click on a feature without navigating to the dashboard each time; the extrude and revolve tools allow you to specify negative direction values to invert materials for offset geometry; extrude is added to offset to eliminate the step of creating intermediate construction features.

PTC Creo 5.0 includes Topology Optimization, Additive/Subtractive Manufacturing for metal 3D printing, Mold Machining, Flow Analysis, Multi-CAD Collaboration, and improved enhancements with geometry sketch regions, subdivisional modeling, surfacing, sheet metal tools, and volume helical sweeps.

Read more about the newest release in our blog called, “What’s New in Creo 5.0?” or download the data sheet here.

Creo Software – Technology of the Future

When you purchase PTC Creo Software, you have the power to publish, share, and create augmented reality experiences right inside of your 3D CAD models. This allows you to add value to your customer experience because they can now visualize your design with AR.

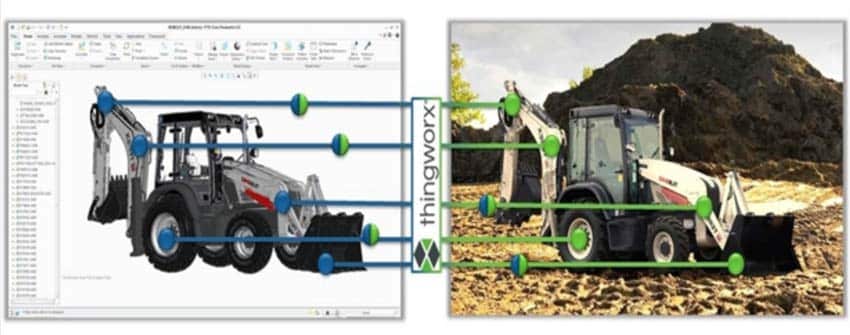

With Creo Parametric, you also have the power of simulating digital twins within your CAD models to collect real-time data from sensors on a physical product. You can reduce downtime while using this data to find performance issues and schedule predictive maintenance.

As the physical and digital worlds converge, digital transformation starting with the right CAD software is more relevant than ever. PTC Creo software eliminates barriers to innovation and is a solution for product development challenges.

Download a free 30-day trial of PTC Creo to see for yourself how the right CAD software gives you the tools you need to design above and beyond anything you’ve ever imagined.

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

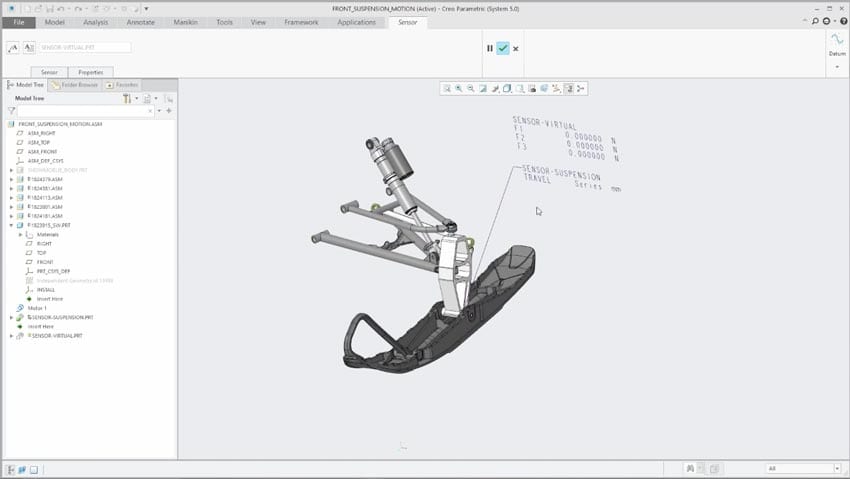

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

- Reuse and instrument released designs

- Embed sensors into new designs

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.

In a recent Tip of the Week video over on our YouTube channel (https://youtube.com/eacpds) I talked about a new feature in PTC Creo 5.0 – Topology Optimization. Topology optimization has been around for about 20 years, but primarily as stand alone solutions. In spring 2018 PTC announced they had fully embedded a solution from the folks over VR&D into their flagship CAD tool.

This is big news because it allows every user to easily optimize designs in new ways; whether designing for traditional manufacturing or additive manufacturing / 3D printing. Light weighting a part or assembly while maintaining structural integrity is an important part of modern product development. Optimizing topology reduces shipping weight and costs, may improve user experience, and lowers material costs. I’m sure there are other benefits, but those alone can help companies compete in today’s global economy.

After talking with some of our technical resources and engineers, it sounds like the built in Creo 5.0 tool does a fantastic job shrink wrapping/finalizing the optimized geometry to ensure the surfaces can be solidified and don’t have any weird overlapping surfaces or gaps. Most topology optimization tools kick out facetted surfaces that still need to be smoothed out in another tool. Creo turns the optimized geometry into a Creo Freestyle surface that can be easily solidified. This is especially important when optimizing parts for 3D printing.

We’d love to show you this Creo functionality live. So, after you watch the tip of the week video, head over to our contact page to request a demonstration.