- Reuse and instrument released designs

- Embed sensors into new designs

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

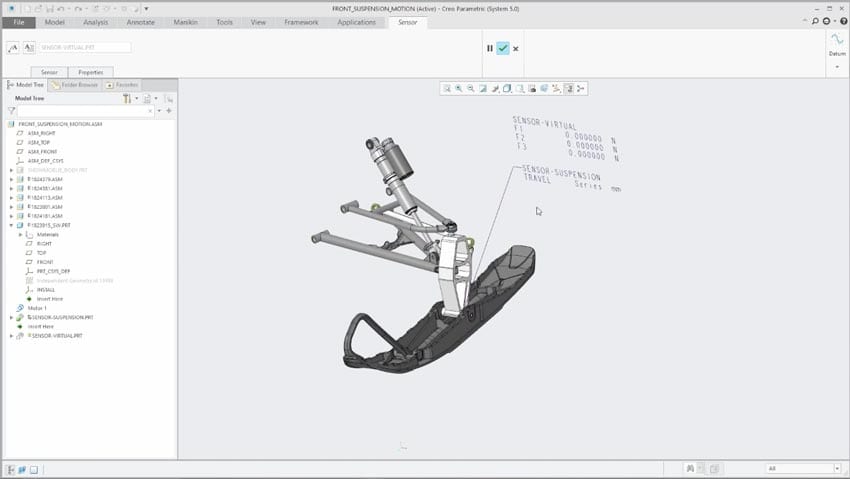

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.

Engineers leverage simulation tools to develop innovative and high-performing products in a virtual design space using computer-aided design (CAD) technology.

Imagine what you could do as a designer or engineer if you could take your simulation a step further and study a digital working copy of a product under actual working conditions. It could help you rapidly optimize the design, life, and maintenance of a product.

What is a digital twin?

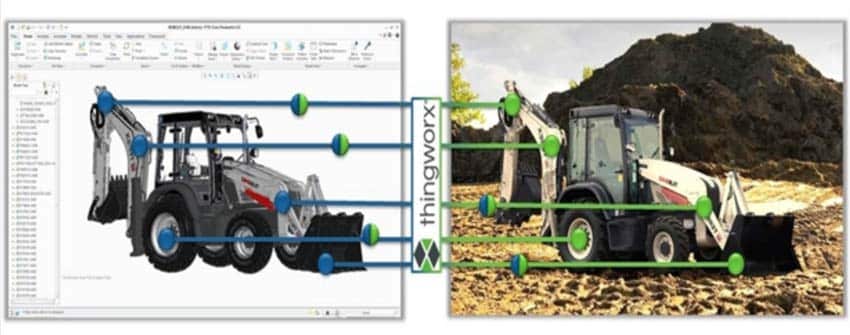

Companies are collecting real-time operating data from product-mounted sensors. They use the data to create an exact replica of a working product, process, or service. This exact replica, called a digital twin, is a simulated model in a virtual space that performs under real-world conditions to help companies find performance issues, schedule predictive maintenance, reduce downtime, and minimize warranty expenses.

Digital twins drive innovation and performance. They give product development technicians predictive analytics and they give companies the ability to improve customer experience. Digital twins allow for better understanding of customer needs, enhanced existing products, streamlined operations, and improved service-after-sales; all while creating headway for new products and services.

The Internet of Things (IoT) has made it possible for digital twins to exist. IoT platforms bridge the gap between the digital and physical world. How does it work? Smart connected products and smart connected operations are connected to a cloud-based system that receives and processes all the data monitored by sensors.

Using the data captured by sensors, the simulation model, or digital twin, is continuously updated and gives designers and engineers the insight they need to improve future product development efforts. (An example would be visibility into real-world bearing operating temperatures and the downstream effects on tolerances right within a CAD model.)

By studying the digital twin under actual working conditions, companies can see the product in action. Engineers can make more informed choices during the design process and use digital twins to make their simulations more accurate.

Bringing digital twins to life with the Internet of Things

For businesses already using engineering simulation to design products, connecting the simulation to the physical product in the field is necessary to deploy the digital twin solution.

For businesses that are new to simulation, the engineering team would first need to build the 3D product model, optimize its performance, and replicate the real world in which the product system would operate. Re-using this data in similar product simulation scenarios for future product development saves time and money.

In process of applying a digital twin to your design is explained in PTC’s blog as follows:

- Build a product using 3D CAD

- Build a physical prototype of the product

- Add sensors to the prototype

- Build the sensors in the 3D CAD model

- Collect the data (E.g., via ThingWorx)

- Associate the sensors’ data streams to the sensors in your 3D CAD model

- Voila! Now your model can talk.

Not only do digital twins improve future innovation and product development efforts for designers and engineers – they build a stronger relationship between engineering and operations teams.

The data collected from sensors is analyzed by the operations team to optimize performance, service, and maintenance over the lifetime of a product. The digital twin can help organizations avoid costly downtime, repairs, replacements, or stay ahead of other performance issues.