- A clean laser spot via a spatial filter ensuring high precision and accuracy

- A parabolic mirror creating a perpendicular laser spot for uniformity across the build platform

- Soft release from a flexible tank enabling easy cleanup by requiring small, minimal supporting

- High performing future materials

- User-replaceable LPU with garage mode to protect optics

- Adaptive print speed for perfect balance of speed and detail

- System scales for large format 3D prints

Formlabs 3D Printer: Form 3

What makes the Form 3 the best 3D printer out there?

The Form 3 combines a flexible tank and linear illumination to deliver incredible print quality and printer reliability through a new Low Force Stereolithography (LFS) process.

The flexible tank lowers the forces exerted on the part during printing to provide incredible detail and surface finish, and allows for light-touch support structures that easily tear away. The Light Processing Unit uses a system of lenses and mirrors to direct a precise, uniform high-density laser spot.

How accurate is the Form 3?

The Form 3 prints with 25 micron XY resolution and 25-300 microns (user selectable) in the Z, using an 85-micron laser. Accuracy depends on many factors such as the print performance of an individual resin.

How fast is the Form 3?

The Form 3 delivers the perfect balance of detail and speed. Print times will be comparable to Form 2. A new material, called Draft Resin, was specifically developed for fast printing at 300-micron layers for engineering parts where a fast turnaround is critical.

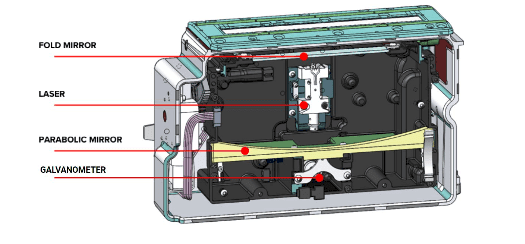

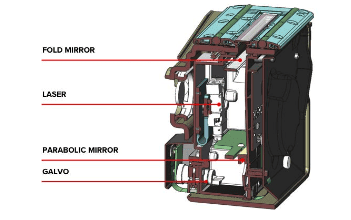

How does the optics module work?

The custom-designed Light Processing Unit (LPU) inside the printer is built to deliver accurate, repeatable prints, using a compact system of lenses and mirrors. During printing, the LPU moves in the X direction, while the high-frequency galvanometer inside positions the laser beam in the Y direction, then directs it across a fold mirror and parabolic mirror to deliver a beam that is always perpendicular to the build plane. The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot.

What layer thicknesses are available for Form 3?

25 – 300 microns (.001 – .012 in) . See Form 3 tech specs here.

Formlabs 3D Printer: Form 3L

How much bigger is the Form 3L build volume?

Five times bigger than Formlabs’ desktop printers: W x D x H: 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in)

How does the build volume for Form 3 compare to Form 2?

The Form 3 has the same XY (145 x 145 mm) as the Form 2 with a slightly larger Z (185 mm versus 175 mm). See the comparable tech specs here.

What are the biggest differences between Form 2 and Form 3?

The Form 3 is built around a new print process called Low Force Stereolithography. Reducing the forces on parts is key to taking a big leap forward in part quality and printer reliability.

Formlabs has made the core optics more powerful, robust, and easier to monitor and maintain with the enclosed Light Processing Unit. A series of filters, sensors, and mirrors ensure uniform light for greater precision and better performance over time.

They’ve also added many sensors that help with overall usability, from correcting user error with a UI guided onboarding process, to more precisely measuring remaining resin.

Finally, there are some great features designed to save time, increase throughput and enable new ways of working. Like fine touch supports that reduce part finishing time and improve underside surface finish, and the ability to prime a printer to remotely start a print overnight, allowing you to respond to just in time requests.

That said: the Form 2 is an award-winning, tried-and-true machine, and is now available at an even more affordable price point.

How does the Form 3 peel force compare to the Form 2?

The force on a part depends on the part geometry and material. In their internal testing, Formlabs has seen force reductions anywhere from 3 – 10x compared to the Form 2. Reducing the forces on parts while printing allows you to print with fewer and lighter supports. Lower forces also allow us to better capture fine detail and smooth surfaces with minimal layer lines, and result in improved print success and overall reliability.

What parts are cross-compatible between Form 2 and Form 3?

Many components are cross-compatible between the two printers. The build platform, resin cartridges, Form Wash and Form Cure, PreForm, and Dashboard are compatible across both machines. The standard Finish Kits are comparable with the addition of the tank tool for Form 3.

These are the most frequently asked questions for Formlabs’ new 3D printers, the Form 3 and the Form 3L. Please reach out if you have any questions that weren’t answered here.

Don’t forget to follow me on LinkedIn to check out my tips and tricks on how to use Formlabs 3D printers and trends in the additive manufacturing industry!

The next generation of Stereolithography (SLA) 3D printing is here… and we’re here to tell you about it!

Formlabs introduced two new printers, the Form 3 and the Form 3L, using a process called Low Force Stereolithography (LFS) to bring you advanced 3D prints. This new additive manufacturing technology gives you the ability to create better and more affordable parts and enables production-ready applications with higher production volumes.

Let’s get down to the basics.

What is stereolithography (SLA) 3D printing?

The SLA 3D printing process is known for creating a smooth surface finish and detail using a laser to cure solid isotropic parts of liquid photopolymer resin. The Form 2 SLA 3D printer process allows for lower production costs to manufacturers than most 3D printing industrial machines and it leaves a smaller footprint by using less material.

What is Low Force Stereolithography (LFS)?

Low Force Stereolithography (LFS) is an advanced form of SLA printing that uses a flexible tank and linear illumination to turn liquid resin into flawless parts. LFS technology produces all the benefits of SLA technology plus the following features:

Low Force Flexible tanks work by the build platform pulling up the part and gently releasing it from the film. When you have a more flexible tank, you get lower force, which allows for better print quality and better printer reliability. Lower forces on the part lead to incredible detail and surface finish, easier support removal, and cutting-edge material possibilities.

The Components of LFS 3D Printing

Condensed optics module: A custom-designed Light Processing Unit (LPU) inside the printer uses a compact system of lenses and mirrors to deliver accurate, repeatable prints.

Flexible Tank: The bottom of the resin tank is a flexible surface that enables a massive reduction in peel forces while printing.

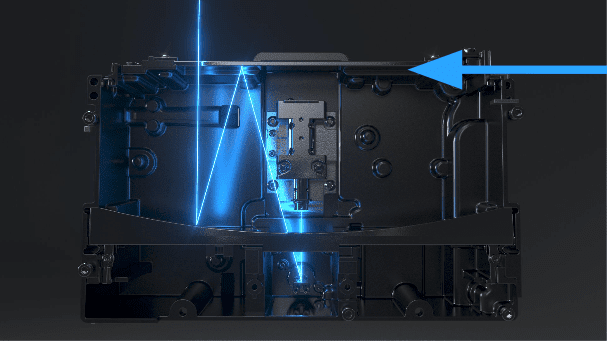

Linear Illumination: The high-powered laser from the LPU coupled with the parabolic mirror provide a crisp completely perpendicular curing source during the LFS 3D printing process.

The Benefits of LFS 3D Printing

- Pinpoint precision for flawless prints

- Balances high detail and high speed

- Faster printing with a high frequency galvanometer

- Many integrated sensors to monitor performance for reliable, nonstop printing

- Fine-touch support touch points

- Better printing for resins with higher viscosity and lower green strength

How linear illumination creates precision and uniformity with parts

Linear Illumination = Precision + Uniformity = Accurate, Repeatable Parts

One galvanometer positions the laser beam in the Y direction. The beam is then directed to a fold mirror and parabolic mirror so the beam is:

1) Always directed perpendicular to the build plane (uniformity/consistency)

2) Always moving in a straight line (precision/accuracy)

What is an LPU and why does it matter?

The LPU is one of the most revolutionary components of Formlabs’ LFS 3D printing technology. The Form 3 contains 1 LPU unit where the Form 3L contains 2.

The LPU holds the laser, the galvanometer, and a system of lenses and mirrors. The parabolic mirror maintains a perpendicular path to the bottom of the resin tank at all times, making for consistently clean, crisp edges and smooth surfaces.

The LPU is a single replaceable part located in the main printer body that folds almost every optical component of the printer into a small metal housing unit.

Rather than containing two galvanometers like the Form 1, Form 1+, and Form 2, the LPU contains just one galvanometer that controls the direction of the laser, as the entire LPU unit moves across the build area.

The main four components of an LPU galvanometer are the fold mirror, the laser, the parabolic mirror, and the galvanometer.

Features of a Light Processing Unit (LPU)

- Highly Precise, Consistent Laser

- Telecentric Laser Beam

- The laser beam in the LPU is always perpendicular and in constant focus at the print plane, thanks to the galvanometer and the parabolic mirror

- This results in the best possible print quality that is uniform, highly accurate, and consistent across the entire print plane

- Telecentric Laser Beam

- Custom high-power module

- Custom high-power-density laser module

- The laser has a spot size of 85 microns (40% smaller than the Form 2!) and a 25% higher power at the print plane due to the improvements in optical path efficiency in the LPU

- This multi-lens system with spatial filtering reduces stray light to sharpen edges even further and ensure consistent, pinpoint precision which creates smoother surfaces and high dimensional accuracy on printed parts

- Custom high-power-density laser module

- Custom high-frequency galvanometer

- The custom galvanometer combined with other features (like adaptive print speed and not needing to use the mixer between layers) allows for fast print times and consistent quality

- Modular and scalable

- Bigger prints (at an affordable price) designed to scale. For the Form 3L, two of the same modules are used as the Form 3

- Self-diagnostics

- Reliability: Constant sensing and automatic calibration

- Field replaceability

- Uptime: No need to swap out your printer to replace the laser or other key optical components

Now that you know how Low Force Stereolithography works, you’re better informed on how you can use Formlabs’ new 3D printers, the Form 3 and the Form 3L.

Reach out if you have any questions, and don’t forget to follow me on LinkedIn to check out my tips and tricks on how to use Formlabs 3D printers and trends in the additive manufacturing industry!

The Form Wash is designed for the Form 2 3D printer from Formlabs to automate the cleaning process between printing parts. It makes things much easier for engineers who don’t want to waste any time cleaning their prototypes so they can either use the Form 2 again for another print job or get back to their next project.

Washing printed parts before post-curing helps to remove excess residual resin from part surfaces and cavities. Formlabs suggests using isopropyl alcohol (IPA) as the solvent that is most compatible with washing.

If you take a look at the image above, you can see that the left part is much cleaner and visually is more detailed than its counterpart. After using the Form Wash, you can typically use the Form Cure to expose printed parts to light and heat to stabilize the parts for performance. Using the Form Cure is not necessary but using the Form Wash and Form Cure together is recommended for optimal finishing.

Colder Products Company (CPC) has trusted EAC for years to provide them multiple Form 2 printers and other Formlabs equipment and materials to rapidly prototype customized quick disconnect couplings, fittings, and connectors for plastic tubing used around the globe. We answer a few questions that users have about the Form 2 and also include an engineer’s intake as well. Here is how Jeff Martin, an applications engineer at CPC, uses the Form Wash in-house to reduce time spent cleaning 3D printed parts.

How much time does it take for one wash?

Formlabs says that most resins require washing for the Form Wash default programmed time, which is 10 minutes – although additional time is needed for some resins. The following table shows Formlabs’ recommended wash times for each resin being used.

| Resin | Wash Time | Resin | Wash Time |

| Tough | 20 min | Elastic | 10 min + 10 min |

| Rigid | 15 min | Dental SG | 5 min |

| Grey Pro | 15 min | Dental LT Clear | 5 min |

| Castable | 10 min | Denture Teeth & Base | 10 min |

| Castable Wax | 10 min | Ceramic | 5 min |

| High Temp | 6 min | All other resins | 10 min |

Jeff suggests that you should set your wash time at 20 minutes for each wash. He also recommends that it’s best to physically have 2 Form Washes in-house to speed up the cleaning process, “The first Form Wash set to 10 minutes to wash parts hanging from the build platform, and the second Form Wash is used to clean the parts broken free from supports.” (Keep in mind, he typically uses Rigid Resin for his 3D prints).

What’s the best way to wash prototypes?

If you’re using the Finishing Kit, Formlabs recommends that you should wash your prototypes in at least two standard wash tanks – the first wash, being the ‘dirty’ wash, would take 10 minutes and then the second wash, using a cleaner tank, for another 10 minutes. Once the first tank gets dirty, you can dispose the IPA, transfer the second tank into the first tank, and then pour new alcohol into the second tank.

The Finishing Kit includes 2 wash tubs to manually clean your 3D prints – whereas the Form Wash automatically cleans your parts and prototypes.

Jeff says the advantage of having a second Form Wash is that you can use Formlabs’ same theory of having a clean tank to do the final rinse. “I find it in my experience to be extremely useful to remove the supports for the second wash. The reason is that the supports block the fresh circulation of clean solvent from the parts. You will notice that for deep aspect bores and blind holes, if you do not remove the supports, they often times will not fully be cleaned of resin. After removing the supports and letting the parts bounce around in the basket during the last 10 minutes, they will always come out clean.”

Learn more FAQ by reading our related blog, “Everything You Need to Know About the Form 2 3D Printer.” If you’re interested in a free sample, then contact us at your earliest convenience.

Also, follow me on LinkedIn for tips and tricks on how to use the Form 2 and other equipment and materials from Formlabs!

You can now find the softest material for 3D printing, Formlabs’ Elastic Resin, and the most pliable of their library of Engineering Resins available to purchase through national commercial reseller EAC Product Development Solutions.

Request a free sample part to see how soft and silicone-like the Elastic Resin feels.

Elastic Resin

The Elastic Engineering Resin has a 50A Shore durometer material suitable for prototyping parts normally produced with silicone. This soft stereolithography (SLA) resin is highly elastic, yet strong enough that it doesn’t tear during the print job. Usually, these types of flexible prototypes have to be produced with mold making, but the Form 2 makes it possible to produce these models in a matter of hours in-house.

You can use Elastic Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing. Typical key applications for soft silicone and urethane parts include wearables and consumer goods prototyping; medical visual simulation and devices; compliant features for robotics; and special effects props and models.

This new resin is a long-lasting, tear-resistant, and made of resilient material that can withstand repeated use. It should be noted that soft 3D printing materials, in general, require denser support structures and attention to specific design guidelines before you print.

Real-use applications in various industries

Medical Industry: The Elastic Resin is translucent – a color ideal for medical visual applications and device prototyping. Anatomical simulation models, artery and vessel models, prototyping silicone parts.

“Elastic Resin’s opacity illuminates internal cavities well and its durability means that educators, trainees, and clinicians can handle and examine models without the worry of breakage. This material will be of particular interest to cardiovascular surgeons and interventional radiologists, as well as those conducting fluid dynamics studies and working in catheterization labs. It is relatively cost-effective when compared with other similar materials on the market, which can only help accelerate the adoption of 3D printing in medicine.” -Sanjay Prabhu, MBBS, FRCR; Pediatric Neuroradiologist and Clinical Director, SIMPeds3D, Boston Children’s Hospital

Engineering and Product Design: For those that are using Flexible Resin already, the Elastic Resin is a softer option for consumer product development. Prototyping silicone parts and seals, soft pads, grips, and ergonomic features, as well as sports eyewear.

Comparing the Elastic Resin to the Flexible V2 Resin for engineering and product design applications:

| Elastic | Flexible V2 | |

| Durometer | 50A: a soft flexible material | 80A: a hard flexible material |

| Elongation | High (160%) | Medium (80%) |

| Energy return/ spring back | High | Moderate |

| Tear Strength | Better (19.1 kN/m) | Prone to tearing (13.3 kN/m) |

| Reaction to compression | Good energy return/spring back | May break |

| Color | Translucent | Dark Grey |

Print resolutions: 100 microns only. Post-curing required. LT Tank Required. Good elongation (160%) and tear strength (19.1 kN/m). Wash time: 20 minutes. Cure time: 20 minutes at 60 °C.

Price: $199/L

Learn more about the Form 2 on our website. Or contact us about ordering the Elastic Resin.

Start Printing with the Form 2 3D Printer

The following is a case study pertaining to how CPC has used the desktop Form 2 3D Printer to transform the way they meet the demand of their customers.

If you want to start seeing results like CPC has, then contact us or request a free sample today.

Business Overview

Colder Products Company (CPC), founded in St.Paul, Minnesota in 1978, is a global provider and leader of quick disconnect couplings, fittings, and connectors for plastic tubing. They represent the fluid segment of their parent company, Dover Company. CPC designs and manufactures safe products and fluid systems in the following markets: life sciences, bioprocessing, thermal management, industrial, and chemical handling. CPC has produced over 10,500 custom and standard products to meet the fluid handling challenges of these industries worldwide.

Business Challenges

CPC understands the importance of custom manufacturing designs to meet customer needs. The need for custom parts can make design reviews a challenge. CPC knew the impact that physical prototypes have and how they could increase customer confidence in their designs.

Their options for producing a physical prototype were limited: a steep-priced PolyJet 3D printer used to print design prototypes in-house or outsourcing the prototypes to external vendors. Using a single in-house PolyJet was inefficient due to frequent repairs and maintenance and the difficulty of servicing and cleaning the machine. When outsourcing prototypes, it could take weeks to get a single part shipped.

Patrick Gerst, Vice President of Engineering at CPC, stated, “Our products are handled by people with their hands. The ergonomics of what it feels like when you connect and disconnect our product are all important parts of our brand and features. It’s all about getting customer feedback quickly. Being able to prototype has been a huge selling tool for us on the custom side of our business.”

When using the in-house PolyJet or outsourcing the prototype wasn’t an option, the engineers relied on 3D-rendered computer-aided design (CAD) models to present concepts and receive feedback early on through web meetings. It was a challenge for CPC to convey the size and scale of their designs to their customers behind a computer screen. The need for reduced design cycle time, a more cost-efficient solution, and an accurate portrayal of their concepts and designs were crucial for a better development process and higher customer satisfaction.

Solutions

CPC knew that physical prototypes played a critical role in their development process and customer satisfaction. Jeff Martin, an Applications Engineer at CPC, stated, “Being able to get prototypes in customers hands helps keep their interests piqued. It just keeps the excitement level there.” The mission was to find an affordable 3D printer that required little maintenance and delivered fast turnaround for their increasing requests for customized parts.

CPC compared and evaluated the quality and cost of 3D printers from nationwide and local manufacturers. EAC Product Development Solutions, a local value-added commercial Formlabs reseller, worked with CPC to showcase the Form 2 and its outstanding print capabilities. Martin says, “We evaluated everything from the really large, expensive industrial machines that were over $100,000 to desktop 3D printers. We found that the Form 2 could print the parts equivalently for our needs.”

Results

The Form 2 is a revolutionary stereolithography (SLA) desktop 3D printer used to create models, prototypes, and production parts. The 3D printer has the capability to print at high resolution which allows small, detailed features to be generated with precision – which is exactly what CPC needs for its manufactured parts. The Form 2 is priced as low as $3,499. The affordability of the 3D printer allowed CPC to purchase three Form 2 printers from EAC within 18 months. Purchasing three Form 2’s was $85,000 less than one large industrial printer.

Gerst says, “It was more expensive to maintain our PolyJet than to just buy a few Form 2 printers. If we had a service call, it would cost us a few thousand dollars… It made sense to start going towards these machines.” Compared to the use of one PolyJet, the three Form 2 printers provide a 100% uptime because there is always at least one printer available for a project at all times.

Before the adoption of the Form 2, outsourcing parts slowed down the early design stages for each project. One of their engineers said, “When we only had external resources making our parts, it used to be a rarity that we would buy 3D printed parts. Once a month we would buy some parts at the end of a design cycle and we would have to wait at least a week before we would have anything.” The Form 2 printer allows CPC’s engineers to get a physical prototype in their hands 80-97% faster than if they were to outsource to a service bureau.

“We’re all about iterating and prototyping quickly to learn as much as we can with each iteration. Having multiple in-house Form 2 printers has really helped us accelerate our design time. I don’t think that I’ve ever walked into our design lab and seen all three sitting idle. They run all the time. Now we present prototypes more frequently to customers than we used to,” Gerst stated. With all three printers running continuously, the Form 2 reduces CPC’s design iteration time by up to 80%. Overall, customer satisfaction rates increased due to the quick turnaround time for printed parts from the Form 2 SLA desktop 3D printer.

Have more questions? Here’s everything you need to know about the Form 2 3D Printer.

You asked we answered. Check out what makes the Form 2 3D Printer the best SLA 3D printer on the market.

What’s the difference between the Form 2 3D printer and a filament printer?

FDM or FFM (fused deposition and fused filament) 3D printers melt a plastic filament, whereas the Form 2 uses a liquid photopolymer resin which is cured with a UV laser.

What makes the Form 2 printer better than a filament (FDM) printer?

The Form 2 3D printer can achieve a much finer X, Y, and Z accuracy than most FDM printers because it does not extrude a thick bead of hot plastic onto the build platform. The Formlabs Fo allows the 3D printer to create dense, isotropic parts with greater strength, smoothness, and detail.

How much calibration does the Form 2 require?

Virtually none. Formlabs’ factory calibration rig ensures that printers are fully calibrated. You do not need to do any tray-leveling. The printer is ready to print within 10 minutes of unboxing.

What is the X/Y accuracy on the Form 2 Formlabs 3D Printer?

The Form 2 printer has an accuracy as fine as .002” or 0.050 mm.

What is the tolerance and fit of Formlabs Form 2 Printer?

You can read all about the Formlabs Form 2 tolerance and fit on this accuracy, precision and tolerance in 3D printing guide.

What is the resolution of the Form 2 printer?

The Formlabs Form 2 3D printer is not an FDM printer, therefore resolution doesn’t pertain to the printer itself. What may be most helpful for you about the Form 2 is the laser spot size, z-axis layer height and the layer thickness (all mentioned in the next few questions below).

What is the Form 2 laser spot size?

The Formlabs Form 2 Laser spot size is 140 microns.

What is the Form 2 3d Printer layer thickness?

The Form 2 has a layer thickness of 25, 50, and 100 microns.

What is the minimum feature size of the Form 2 Formlabs 3D Printer?

The Form 2 has a 150µm minimum feature size.

How big can you print on the Form 2?

The Form 2 build volume is 145 mm x 145mm x175mm (5.7” x 5.7” x 6.9”).

What Form 2 materials can you use with the 3D printer?

The Form 2 3D printer has many standard resins options as well as engineering resins that deliver specific material properties. You can use standard resins that are available in clear, grey, black, and white. The Form 2 also has functional resins that are ideal for a wide range of applications.

The Form 2 flexible resin is ideal for prototyping functional grips, seals, and soft robotics.

The Formlabs tough resin is a durable and impact-resistant material for sturdy engineering prototypes. The Form 2 castable resin material is a great for printing detailed jewelry models that can be burned out in investment casting. The Formlabs Dental SG resin material is a Class I Biocompatible material suitable for printing surgical guides.

What Formlabs Dental resins are available?

There are a few different Formlabs dental resins available for a range of applications. The Form 2 Dental Model Resin is designed for crown and bridge models with removable dies. It is a very high accuracy resin with a smooth matte finish. The Dental SG Formlabs resin is Class 1 biocompatible and is designed for printing surgical guides. The Dental LT Clear Formlabs resin is Class IIa long-term biocompatible and is designed for splints, retainers, and other direct-printed long-term orthodontic applications.

Will the resin harden on the Form 2 3D Printer and how does that work?

The Formlabs resin contains a photo initiator which when activated causes short chain monomers and oligomers to bind together into long-chain polymers which cause the resin to solidify.

How many prints can you get on the Formlabs Form 2 3D printer from 1 liter of resin?

Our standard rook uses about 11ml of resin, so you could get about 90 3D prints from 1L of resin.

What do I do with unused resin after I finish a print job on the Form 2 3D Printer?

Resin left in the Form 2 tank after a print job should stay in the tank. It does not need to be poured back into the cartridge.

What is the shelf life of the Form 2 resin materials?

If the Formlabs resin materials are stored within the cartridge, the resin has a shelf life of about a year, and if stored within the light-blocking resin tank it can be stored safely for about 2-3 months.

How does finishing work on the Form 2 by Formlabs?

When a 3D print from the Form 2 is finished, there is a thin layer of uncured resin which needs to be washed off. When the print is complete, simply soak the part in a bath of isopropyl alcohol for about 15-20 minutes to wash off the uncured resin.

Why do I need the Form Wash and Form Cure units?

When you remove a part from the Form 2 printer there will be a thin layer of uncured resin that you’ll need to rinse off. The FormWash unit uses an impeller to agitate Isopropyl alcohol to get your part clean (see attached FormWash guide -called wash and cure sell sheet). The FormCure unit cures the part to bring it to its maximum mechanical properties. See guide (attached as How mechanical properties of SLA 3D prints are affected by UV curing)

What is the recommended Formlabs cure time?

This all depends on your design. Check out our guide on post-curing with the FormCure for specifics.

How do I get a free Formlabs sample?

See the quality of a Formlabs Form 2 3D prints for yourself. You can request a free Form 2 3D printed sample here.

What maintenance does the Form 2 3D Printer machine require?

The Form 2 requires very little maintenance. The calibration process is done at the factory. The resin tank is a consumable component which will eventually need to be replaced after about 2L of prints. The resin tank costs $60 to replace.

What is the difference between laser SLA and DLP?

Laser SLA printing uses a round laser point to trace out the area to be solidified in each layer. DLP projects a single image of each layer, composed of rectangular pixels, in a flash of light. DLP pros: smaller minimum exposure size, faster prints. DLP cons: build volume is constrained by x/y resolution; projector bulbs are consumable and need to be replaced; pixels lead to voxelization/aliasing error in x/y plane. Also, the Form 2 has a much smaller footprint than most DLP printers and can fit more comfortably in most workspaces.

Why should I consider a Formlabs Form 2 3D printer if I’m already using a Stratasys or an Objet printer?

We’ve found that Form 2 is much less expensive to operate than larger-volume printers, and usually fits nicely within most workflows. This is exactly why we decided to partner with Formlabs adding their 3D printers into our product line. Even if you’re happy with your Stratasys or Objet printer, you may find that using the Form 2 for prototyping smaller parts will save you money in the long term by reducing the operating time and materials cost on your larger machine, while producing parts of a similar quality.