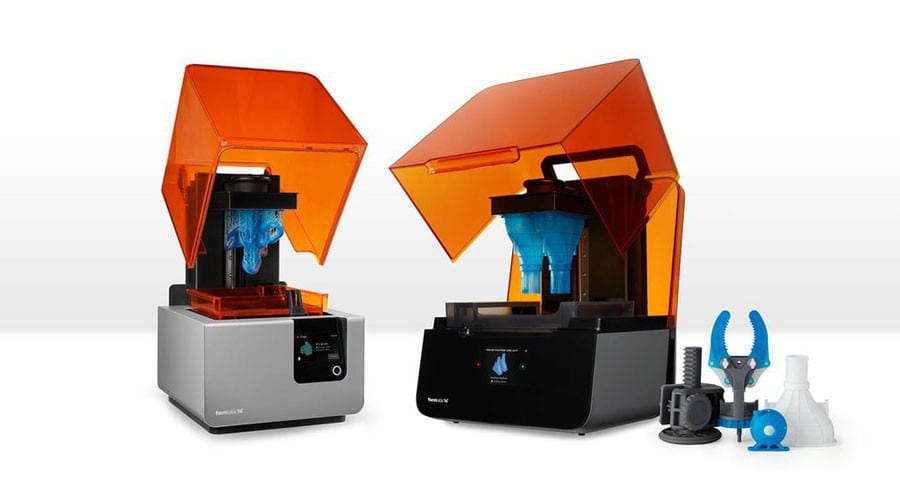

- Knowing the difference between the Form 3 and the Form 3B

- Form 3B 3D printer price

- Resin compatibility with the Form 3B

- Ordering free dental sample parts

Here are the top 10 blogs that our readers loved from this year:

10. Form 3B: Formlabs New Biocompatible 3D Printer

Formlabs released a new Form 3B 3D printer for biocompatible materials. Read the blog if you’re interested in:

9. New Soft, Elastic Engineering Resin from Formlabs

Formlabs released a new Elastic Resin – highly elastic and strong material for prototypes and parts. This new resin is a long-lasting, tear-resistant, and made of resilient material that can withstand repeated use. You may be interested in knowing more if you can relate to these use cases:

- Wearables and consumer goods prototyping

- Medical visual simulation and devices

- Compliant features for robotics

- Special effects props and models

8. PLM Apps Benefit Business

Most companies lose a lot of time and money when employees are challenged with finding relevant, up-to-date product data. According to the Harvard Business Review, workers waste approximately 50% of their time locating data, finding and correcting errors, and searching for sources to confirm the accuracy of data. PLM Apps can help.

If you manage PLM systems and organize CAD data within your company you’ll find this blog helpful. In it you’ll read about:

- How PLM apps are meant for ease-of-use with your PLM system

- How multiple PLM softwares can be integrated

- How PLM apps controls security and access to desired teams

- How customized PLM apps can align with your business strategy

7. ERP vs PLM – What’s the Difference?

We have you take a deep dive into your digital transformation initiatives – which in return, will help you develop the skills to choose the right technology for your organization. This blog breaks down:

- What’s trending in ERP & PLM enterprise systems

- The differences and similarities between ERP & PLM

- How you can use ERP & PLM together for most impactful ROI

- PTC Windchill PLM software and its integration with other systems

6. Bill of Materials Management- What You Need to Know

If you have experience with bill of materials (BoMs) or are just learning about it – you may want to brush up on the info in this blog. We cover:

- Defining bill of materials: ebom, mbom, and sbom

- Importance of accurate BoM processes and reporting

- How BoM management plays a role in system integration

- Custom bill of materials app – BoM Reports

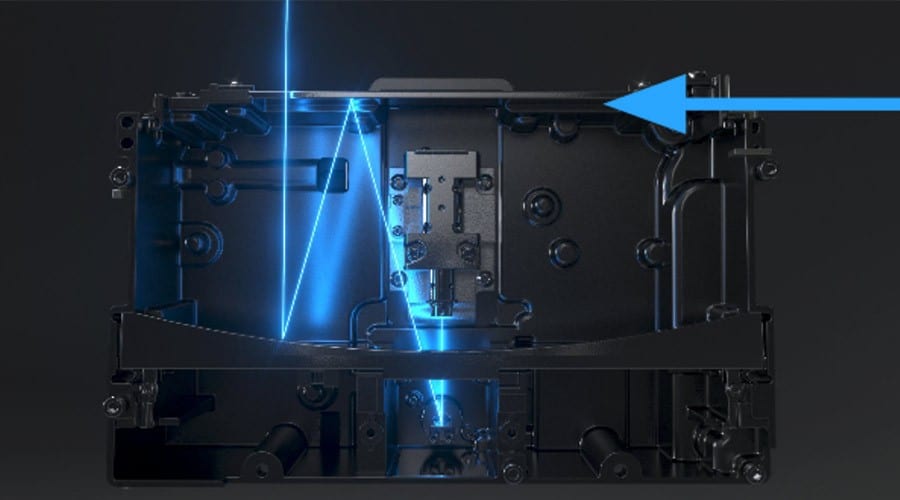

5. Formlabs Releases New 3D Printers using LFS Technology

Formlabs retired the Form 2 SLA desktop 3D printer and released 2 new printers at the beginning of the year – the Form 3 and Form 3L. Read this blog to find the answers to these questions:

- What are SLA and LFS 3D printing? And how the processes different?

- What other technologies are leveraged with LFS?

- What are the benefits of LFS 3D printing?

- What is an LPU and why does it matter?

4. PTC Mathcad Prime 6.0 is here!

Mathcad 6.0 is the newest release of PTC’s engineering calculations software for engineers. The release is meant to help improve your productivity and overall usability to make your job easier every day when it comes to math notations in product development.

Here are some of the new improvements:

- Customized margin dimensions, including headers and footers

- Spellcheck, multi-language keyboard, and hyperlinks have been added

- 2D ChartApp options such as exporting your plot as an image file

- New symbolic calculation engine

3. Form 2 vs Form 3: Formlabs SLA 3D printer comparison

If you’re wondering how the Form 3 compares to the Form 2, we’re able to tell you the differences between the two Formlabs 3D printing machines. The Form 2 is no longer available for purchase – but we’ll point out the improvements in the Form 3 (which IS available for purchase) such as:

- Why LFS (Form 3) is better technology than SLA (Form 2)

- Easier support removal for nearly finished prints

- Flexible tank reduces stress during peeling process

- More precise detail and quality 3D prints

2. Formlabs Form 3 & Form 3L: Answers to your FAQs

- How accurate is the Form 3? How fast is the Form 3?

- How much bigger is the Form 3L build volume?

- What are the biggest differences between Form 2 and Form 3?

- What parts are cross-compatible between Form 2 and Form 3?

1. What is PTC Windchill Software?

If you’re looking for a new PLM system to add to your organization – try PTC’s Windchill. We’ll break down everything you need to know including:

- What’s the origin of PTC Windchill software?

- How much does Windchill PLM cost?

- PLM products: PDM Essentials, PDMLink, ProjectLink, PartsLink

- Admin, support (Alliance Program), and certified training

Communicating product data across an organization is complex. Let’s talk about how to make it easier.

Different departments gather product data from a variety of systems including Product Lifecycle Management (PLM) Systems, Enterprise Resource Planning (ERP) Systems, Manufacturing Execution systems (MES), and Quality Management Systems (QMS) and more, how do we know our organizations are making the most out of all this information?

Just think about it for a second. Our systems speak different languages, AND our departments often aim for different goals.

With an estimated 90% of the world’s data created in the last two years alone (Conner, n.d.), it’s no wonder that companies are having a hard time using it all. The IDC estimates that just 0.5% of the data companies produce is ever used. It’s time to change that.

Here are 9 Ways Your Business Will Benefit From Connecting Your Data systems.

1. Increased Usability

Data experts believe that if Fortune 1,000 companies increased the amount of data they used by just 10%, they could realize over $65 million in additional net income (Marr, 2015). Not only are these numbers huge, they also help make my case about the critical importance of data usability.

The truth is – any one specialized system is often too complex for many non-specialized roles to navigate, find, and transfer the right information. This often leaves separate departments accountable for storing and sharing uncontrolled, out of date versions of product data. It’s not because they don’t WANT to use the right information. It’s because system complexity and interdepartmental gates make it hard to consistently get the right information.

So how do we make product data more usable?

A) Consolidating product data from disparate sources into one single system.

B) Give users a way to access the system using simplified role-specific dashboards.

2. Better Data Access

The most important reason your product data shouldn’t (internally anyway) be kept secret is because product data is your company’s most valuable asset.

Not everyone who needs access to specific product information hosted in your PLM system is from your engineering department, so don’t force them to go through the same vigorous Product Lifecycle system training. Don’t make them navigate an engineer’s world one click at a time.

In order to effectively use data, our departments must have ready access to it. We must make rich product information easy to accessible for a broad set of roles.

By creating an organized system that connects all of our product data, your organization will make information easily accessible to users beyond those who have created it.

Just think of the possibilities that come from connecting multiple systems and delivering information to all departments through a single window.

3. Complete Data

Imagine an entire enterprise with access to real data, at the right time, when it’s needed.

By connecting your product lifecycle management systems with your other enterprise systems, every stakeholder within your organization can impact the value flow of product data through your organization. It also equips team members to consistently drive critical decisions with the latest, most accurate information.

4. Better Insights

Better access to data = Better insights.

Your business teams can and should demand a lot of your PLM processes and solution.

This is one of the reasons why your organization should consider integration technologies and custom front-end solutions – Such as PLM applications.

A data-driven enterprise with insights into how current products and processes can be optimized can drastically improve productivity. Doing this requires teams to have access to up-to-date, accurate product data.

5. Better Decisions

Ready access to information is especially important to any company developing products.

Users without access to the system of record resort to error-prone workarounds that can result in inaccuracies, quality problems, and waste.

Decisions made from out- of- date inaccurate data threaten product quality and delay time to market.

Providing everyone in your organization with broad visibility into the system of record will drive better, more accurate decisions. This will ultimately improve quality, reduce waste, scrap, rework, and help you meet your time to market goals.

The analytical possibilities that come with connecting your data will help users across your organization make accurate product decisions throughout the entire development process.

6. Better Products

Who doesn’t want to create better products faster?

Providing your organization with universal data access will allow your company to drastically accelerate product development.

How so?

By connecting disparate systems, you will have access to real-time data allowing you to make better product decisions.

Because your decisions and actions are now driven by up-to-date information, you will achieve a higher product quality.

7. Increased Productivity

Why waste time manually reading, entering and analyzing data? It could be automatically collected, filtered, and combined.

By collecting your product data in one system and providing a simplified role-based interface, any user within your organization can access contextual, up-to-date, real-time product information anytime they need.

I guarantee your productivity will grow when your organization is able to plan earlier with manufacturing, order materials sooner with purchasing all while your engineering team is spending less time pulling reports.

8. Increased collaboration

Using a system that provides role-based data access to stakeholders throughout your organization provides every role with an ability to quickly understand the status of a part number and how the parts fit together in a design.

This will not only help mobilize and inform the work of teams throughout the organization, but it will also help maximize the success of your product development.

Giving your team the ability to extend and connect your PLM data into the rest of your enterprise will rapidly increase the overall effectiveness of your organization.

9. Real Results

The ultimate benefit your organization will achieve by connecting your data systems stems from your ability to acquire real results.

What does that mean?

Positive results have a tendency to snowball into more and more success. Results give your organization the confidence it needs to quickly deliver value. Providing access to the right information empowers a team, department, company to reach their true potential.

We want to help your company thrive. Our EAC Productivity Apps give your organization a way to connect disparate enterprise systems and easily deliver role-based dashboards to increase user confidence and productivity.