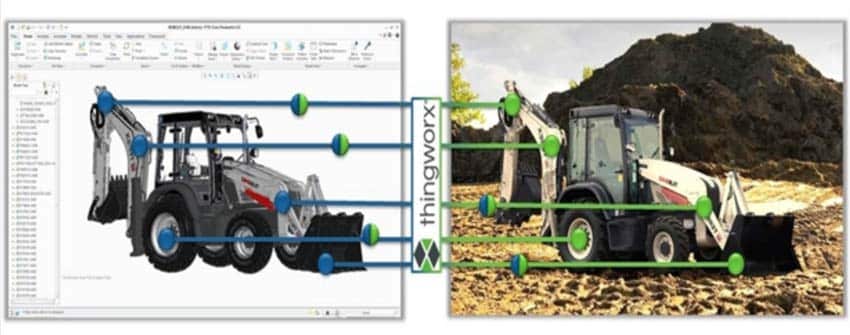

- Reuse and instrument released designs

- Embed sensors into new designs

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

Modernized service strategies combine enterprise IT, ‘smart’ technology, and information.

Manufactures are expected to be more demand oriented, data driven, and technologically focused. This means focusing on the customer, using the data collected from many different areas, and digitally executing strategies using platform technologies.

Many companies today are focusing on the current stage of achieving field service excellence. This tends to be an easier, stand-alone area to focus on as it incorporates vast amounts of technology available to help and support them.

The next stage deals with moving towards connected service platforms which oftentimes involve an integration of smart, connected products. This is when companies will start to deal with how to capture data, leverage the insights, and turn it into actionable results for various stakeholders throughout the organization.

The last stage deals with achieving servitization optimization. Servitization is an important concept because it holds the potential to transform how products are delivered and monetized. This is really the movement towards product service systems and products-in-use value.

Ultimately, providing access to product and parts information is a crucial step in on the path to successful profitable growth.

Technology is fueling service transformation for many organizations.

For instance, here’s how ‘service’ has begun to transform with the help of new technologies:

- Cloud technologies have enabled greater access to service parts visibility and information.

- Mobile technology has put information in the hands of service technicians, at the right time.

- Big data analytics now capture asset and product information, enabling enhanced service quality with better first-time fix rates.

- And social technology has allowed engineers, service, and customer support to collaborate.

These cloud, mobile, social, and big data analytics technologies have enabled manufacturers to transition from systems to service, from information to innovation.

Our team is prepared to help you achieve field service excellence. Our Product Development Information Services team is experienced in the architecture, implementation and support of a technology portfolio making service excellence a reality for many of our customers.

By now, I’m sure you’ve heard the buzz about IoT (the Internet of Things).

‘Start improving the way you do business’, ‘connect with technology’, ‘responsive solutions’, ‘amazing results’.

It’s safe to say that the internet of things along with smart connected enterprises have easily become technology’s theme of the year.

Businesses everywhere have started to look at how they can make more money by inserting this “IoT” thing into their business processes.

The truth behind your success and IoT:

No matter where your journey begins with IoT, it’s essential to recognize good business models rely on technological processes, but technology on its own is not enough.

When it comes to IoT and connected business model innovations, if you don’t have a solid business case, you’re not going to have success.

A connected strategy is about business and business transformation. It’s not just about the technology, it’s about using technology as an enabler.

It’s important to realize there is no value in your IoT platform alone. The real value for you, the success of your business case, lies within your application.

The future is smart and connected.

Whether you choose to build connected solutions into existing products, enter new markets, change your business model, or connect your manufacturing floor; you need to be ready.

Transforming the way you connect with your products, organization, and customers all starts with smart connected design and the right Internet of Things (IoT) platform. The right platform allows you to connect and scale your business.

This is exactly what our company specializes in, in fact we have even created a dedicated connect services team to design and implement custom connected strategies for any organization.

Being able to monitor a product from design into manufacturing, throughout its complete lifecycle makes it possible to improve product quality, increase production, reduce costs, and even predict failures.

Building a smart connected strategy that works for you:

Integrating company initiatives with the Internet of Things needs a strategy, this is what we are here for.

Our connect services team works with your organization to deliver workshops, prescribe technology solutions, and create an IoT strategy that coincides with your company initiatives.

We want to help you define a strategy that makes a connection between your products and operations that already exist within your company and the smart, connected world that we live in today.

We tend to operate our businesses like we’re playing a game of telephone…and it’s costing us all money.

You don’t have to be a genius to know that within many companies’ sales, marketing, and R&D teams serve separate functions. With different goals, targets and initiatives these teams tend to collaborate among themselves using the same system of record.

For example, within the same company, a department may rely on Product Lifecycle Management (PLM) systems while others may depend on Enterprise Resource Planning (ERP), Manufacturing Execution System data (MES), and Quality Management Systems (QMS).

Marketing, Management, Purchasing, Engineering, Technical Publications and manufacturing all need to operate off product designs and Bill of Materials (BOM), but while doing so people are likely to interrupt engineering to get information.

With this information they ask different questions, have different intentions, and speak different departmental languages.

The reality is; this inaccessible data is about the same product that happens to be housed in a system you can’t normally access.

By resorting to these misaligned processes, we end up operating on data without its entire context, therefore we lose productivity to requests for data and the switching costs of changing tasks.

Besides, these interruptions are generally counterproductive, especially when you’re working on one task and you’re interrupted regarding a completely different topic.

Without a single means to bridge these systems, your company is missing out on valuable information, time savings, and productivity.

We live in a world where siloed departmental communication doesn’t need to be the norm, after all technology is just about everywhere!

By integrating your critical data into a centralized location, your organization will increase visibility, and achieve better, more informed business decisions.

With technology that exists today, your separate departments can pull data from multiple systems into easy role-based dashboards, providing greater visibility and enhanced analysis.

The result is a rapid way for your team to get data from the vast data pool within your organization, and access it in an easy to consume space.

One of the ways we transform the way companies design, manufacture, connect, and service their products is by value stream mapping ‘Product Development Systems’ and looking for ways to ensure people have access to the information they need when they need it.

Tools like Thingworx Navigate, for companies invested in PTC’s Windchill solution, or the standard Thingworx platform and PLM Apps for those that aren’t, are helping companies pull information from different departments, systems, vendors, etc. to make sure every role has a simplified view of the information they need, when they need it, without slowing down any other departments.

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

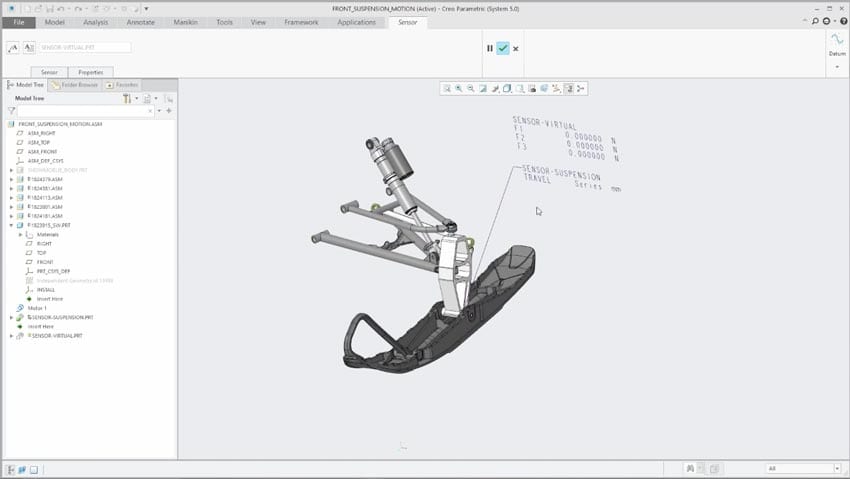

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.

Here’s how connected products are changing service.

Connected products optimize business processes

Lets face it, business is all about efficiency – taking costs and time out of products and processes. This is exactly how connected products optimize business processes.

Connected products provide organizations with access to real-time data that is combined with existing system information to increase efficiency.

For example, you could provide data about your products condition in the field. By doing so, your technicians can be better prepared to troubleshoot. This can reduce the number of onsite visits because technicians have the right instructions or tools required to quickly repair an asset.

Implementing a connected product strategy can improve your first-time fix rate, decrease truck rolls and service calls, and increase the efficiency of your delivery model.

Connected products improve customer experience

Connected products also positively impact customer experience.

Customers recognize more service value when issues are resolved in one call or service visit. Connected products arm your service team with the information necessary to quickly and effectively address service requests and increase customer satisfaction.

Customer satisfaction correlates to service renewals.

Connected products differentiate offerings

With the use of a connected product platform, your organization will be able to increase the pace of product and service innovation, proactively diagnose and service your products all while increasing the speed of your service delivery.

For instance, if your hardware was a commodity or under heavy competitive pressure, improving the software, applications, and service that came along with your products could help differentiate your offering and help you outpace the competition.

Connected products drive new revenue streams

Connected products help drive new revenue streams by unlocking new business models, reducing customer downtime, meeting SLA’s, and by providing offerings such as “product as a service”. Would your company rather wait for occasional service revenue to come in, or would you rather intelligently monitor, maintain, and update your products for a consistent recurring fee?

Information will fuel the future of products and services. Data can be used to improve, differentiate, and optimize your business. The impact the Internet of Things has had on service delivery and customer experience is staggering. Delivering connected products is the first step to realizing the benefits of a connected product service strategy. We’d like to help you realize your strategy, implement industry-leading solutions, and support your implementation and deployment. Let’s connect.

What if a bartender knew exactly when one of their kegs was about to tap out just by looking at a volume meter on an app on their phones? Their bar back could switch out the keg before impatient patrons demand more. What if liquor shelves had weight sensors that measured when someone adds or removes liquor? Or an app on a phone existed that notified management when and what liquor is moved? Or better yet, a storage system that communicates with the front bar, knows which liquor is being moved, and manages inventory according to actual usage? Inventory would be a lot more accurate and there would be less time spent trying to figure out what needs to be in the next order.

When smart connectivity allows for a smoother restaurant or brewery experience, you’re most likely going to have a better time without realizing it had anything to do with the Internet of Things (IoT). For businesses, IoT solutions are creating more opportunities to connect products with the Internet. And for the average consumer, IoT solutions are creating easier access and control of products through smartphones, tablets, and desktops.

![]()

Leaders are investing in an IoT strategy as they plan the future success of their products and services. You can add smart connectivity to your products – even if you’re in the beer industry.

Here are a few industry leaders that leverage the Internet of Things to drive their success.

Deschutes Brewery

Headquartered in Bend, Oregon, Deschutes Brewery has been making craft beer since 1988. You may be familiar with their rich porter Black Butte created with hints of chocolate and coffee or their Fresh Squeezed IPA brimming with grapefruit enriched hops.

The Deschutes team partnered up with a consultant group and Microsoft last year in efforts to improve their brewing process. With a total of nine brewing phases, each phase has to be closely watched to maintain the quality of their beer. Machine learning is the application of artificial intelligence that provides systems the ability to automatically learn and improve from experience without being programmed. Deschutes has implemented machine learning and predictive analysis to automate and improve their fermentation processes. When pairing IoT sensors with the Cortana Intelligence Suite, Microsoft’s predictive learning software, the analytics tool determines the percentage of beer fermented in each batch and predicts when it’s time to switch to the next phase. The Deschutes team can now accurately schedule the nine brewing phases accordingly to ensure the quality of beer is consistent with all of their batches.

Connecting the beer tank sensors with machine learning gave Deschutes an IoT solution and allowed them to improve their brew processes. Deschutes reduced their fermentation process by 24-48 hours. They are now able to focus more time on creating new brands and maintaining the quality of the existing ones. Deschutes is looking at furthering the use of this smart, connected technology by looking into using it for preventive maintenance for their equipment so that brewers would be alerted if parts are due for service or replacement.

Buffalo Wild Wings

Buffalo Wild Wings, headquartered in Minneapolis, MN, is a popular sports bar that has an average of 24-32 beers on tap. Due to major growth of the company and being one of the top 10 fastest-growing restaurants in the U.S., BWW needed to keep up with the growing demand of their customer’s needs. The company faced two major challenges. Both challenges prompted the need to leverage technology and the Internet of Things for an improved operational efficiency.

The first challenge was that they needed to eliminate the product loss that results from comping drinks, excessive or bad pours, and generous bartenders that give beer away without entering the sale in the system. BWW implemented a system called BeerBoard that monitors beer flow data from IoT sensors in the taps to Mulesoft, an Enterprise Service Bus (ESB), where managers can compare beer output to sales information pulled from their Aloha point-of-sale systems. Restaurant managers can accurately determine whether they are running an effective beer operation with the help of the IoT solution found from linking the sensors to BWWs data management systems.

Their second challenge was managing the demand of the assortment of beers for each location all year round. BWW used BeerBoard’s new SmartBar beer management platform to switch and assign new beers corresponding to tap lines. Pour data and sales data would be captured through the platform where all BWW restaurants would have access to the reports to measure performance of each beer. The ability to gain beer preference insight brought a powerful competitive advantage to Buffalo Wild Wing’s brand and reputation.

By working with a few different companies that provided the IoT flow sensors and a software solution to manage their data, BWW started to accurately predict preferences and optimize inventory planning. The company now leverages the Internet of Things to accurately track beer consumption.

How to Bring Your Products to Life with the IoT

Race up the learning curve and find a partner that’s driven to find and implement the right IoT solution for your unique business. Make sure they have the engineering expertise necessary to bring your products to life. EAC Product Development Solutions is a company that transforms the way companies design, manufacture, connect to, and service their products. EAC is on a mission to help companies innovate, optimize, and win in the marketplace by selecting the right IoT solution — like PTC ThingWorx. With ThingWorx allows organizations to connect their products to the Internet and give customers the tools they need for easy access and control.

Ready to dive in? Our team of specialists, engineers, and developers would love to help you bring a working proof of concept to life. The demo application image below is an example of how our engineers can use ThingWorx to pull together data from many sources and deliver data to your fingertips. The demo shows how a local brewery can use the app to access plant conditions, truck tracking, order tracking, weather forecasting, collaboration, and beer tasting — all in real-time simulation.

![]()

Watch our Connect Services video to see how our engineers can connect your products with the Internet of Things!

Knowledge is power. Keep track of your data if you’re not doing it already. You’re bound to learn something from it. Better yet – apply smart connectivity to your process. Contact our Design and Engineering Services at EAC Product Development Solutions to realize your product potential and to find your IoT solution.

Download our free Connect Services Brochure to see how you connect your products to the internet for a smarter technology solution.