- Reuse and instrument released designs

- Embed sensors into new designs

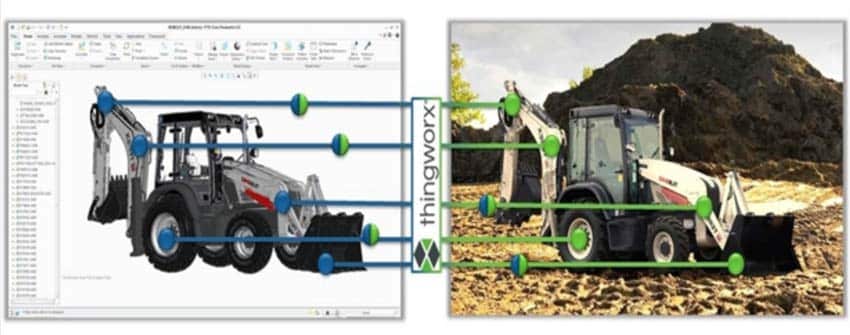

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

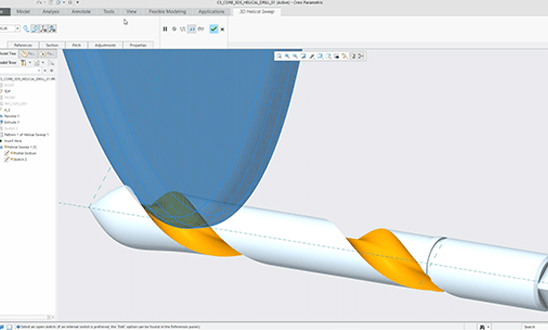

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

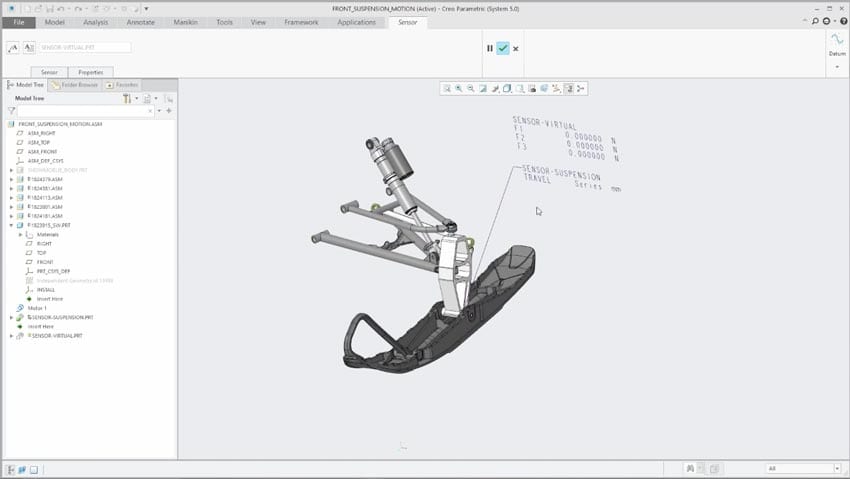

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

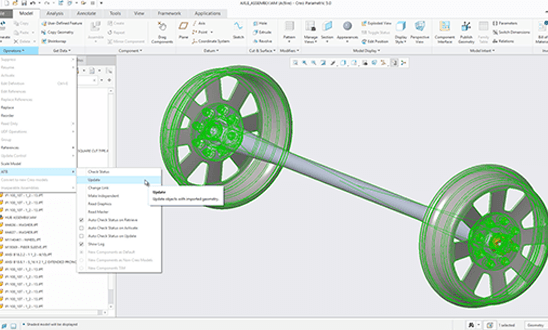

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.

EAC’s been in the engineering and design technology world for a long time. Over the years we’ve carefully cultivated our product portfolio to meet the ever-changing needs of people and companies that design, manufacture, and service products. Our partnerships with PTC and ANSYS allow us to offer a few different design simulation and analysis solutions to our customers.

Design simulation, Computer Aided Engineering (CAE), Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and many other terms all fall into the “simulation and analysis” bucket. These tools help engineers and designers create virtual prototypes of their products. This helps groups rapidly prove, or disprove, design ideas in a digital space – reducing the time and money spent on physical prototypes, and increasing confidence in designs.

“If you’ve seen one, you’ve seen ‘em all” does not apply to simulation software. Different tools offer different benefits, accuracy, speed, and ease-of-use. Here’s a quick overview of some of the tools we offer. Contact our sales group to learn more about pricing, full capabilities, and packaging.

Option 1) PTC Creo Simulate

Simulate is a fantastic tool that’s fully integrated into PTC Creo Parametric CAD software. It offers fantastic meshing capabilities and accurate simulation results directly within a user’s familiar CAD software interface. All you need to do select the PTC Creo Simulate tab and you’re off and running. This is great for designers and engineers looking to test the stresses and loads under which a product will operate in ‘real world’ conditions. Based on your simulation and analysis results, you can either fix design flaws or forestall them. If you’re already using PTC Creo you should explore PTC Creo Simulate. Because, why would you ever manufacture a product without testing and analyzing it first? Creo Simulate comes in two flavors – Simulate and Advanced Simulate. They come with two different price points. One or the other might be the best option for your company. It really comes down to whether you need to simulate materials with linear or non-linear properties.

Option 2) ANSYS Discovery Live

ANSYS Discovery Live blows my mind. This tool was released in late 2017 and delivers functionality never seen before. Discovery Live uses ANSYS Discovery SpaceClaim to pull in IGES, STEP, and CAD models. Then the interface guides users through applying materials and some constraints – and Boom! It runs the simulation…in real-time…right in front of you. I’m talking about the ability to run wind-tunnel testing in real-time! Discovery Live is different from PTC Creo Simulate and most other simulation tools. It uses the Graphics Card (GPU) to run the simulation. This means it doesn’t occupy your core processor and RAM to while solving. You get better computer performance and instantaneous results for structural, thermal, fluid flow, wind tunnel, structural/fluid interaction, and more. Discovery Live is a great tool for engineers and designers that want to test a lot of design options quickly. The price is incredibly reasonable for a tool this powerful. You can see pricing and compare Discovery Live to AIM here.

Option 3) ANSYS Discovery AIM

Sometimes simulating real-world conditions requires more features and control than tools like PTC Creo Simulate, Solidworks Simulation, or Discovery Live might offer. ANSYS Discovery AIM is a great option when that’s the case. ANSYS Discovery AIM is a “multi-physics” simulation tool. What does that mean? Multi-Physics or Multiphysics refers to the ability to combine properties and solvers to simulate product usage. “Physics” in the simulation world refers to the kinds of simulation you are running – e.g. electromagnetic, thermal, structural, radio frequency, fluid flow, etc. AIM is a workflow driven multi-physics tool. It guides users through the steps necessary to complete a successful simulation. This is the perfect option when companies want a robust solution, but may not have experienced analysts on staff. Much like how PTC Creo Simulate maintains a familiar interface to make simulations easier; AIM uses guided workflows to make detailed upfront simulation accessible to engineers and designers.

Option 4) Dedicated ANSYS analysis software

When product simulation and analysis goes to the next level you need the ANSYS flagship products. These are sometimes known as the ANSYS Workbench products. Unlike PTC Creo Simulate or the Discovery software, each of these tools focus on one area of simulation…and deliver results you can take to the bank (or the regulatory agency). They are more complicated and come with a higher price point, but the results are unmatched. ANSYS’ comprehensive software suite spans the entire range of physics, providing access to virtually any field of engineering simulation that a design process requires. Organizations around the world trust ANSYS to deliver the best value for their engineering simulation software investment. If you need to test a specific physic – fluids, structures, electronics, semiconductors, or embedded software – this is the option for you. Contact us to learn more about a specific solution’s pricing and functionality. Also, if you’re a start-up make sure you ask us about special offers available through the start-up/entrepreneur program.

So there you have it. My layman’s take on a variety of simulation options. I hope you found this helpful. Please reach out to us if you have any questions or would like to see a demonstration of any of these tools.

In a recent Tip of the Week video over on our YouTube channel (https://youtube.com/eacpds) I talked about a new feature in PTC Creo 5.0 – Topology Optimization. Topology optimization has been around for about 20 years, but primarily as stand alone solutions. In spring 2018 PTC announced they had fully embedded a solution from the folks over VR&D into their flagship CAD tool.

This is big news because it allows every user to easily optimize designs in new ways; whether designing for traditional manufacturing or additive manufacturing / 3D printing. Light weighting a part or assembly while maintaining structural integrity is an important part of modern product development. Optimizing topology reduces shipping weight and costs, may improve user experience, and lowers material costs. I’m sure there are other benefits, but those alone can help companies compete in today’s global economy.

After talking with some of our technical resources and engineers, it sounds like the built in Creo 5.0 tool does a fantastic job shrink wrapping/finalizing the optimized geometry to ensure the surfaces can be solidified and don’t have any weird overlapping surfaces or gaps. Most topology optimization tools kick out facetted surfaces that still need to be smoothed out in another tool. Creo turns the optimized geometry into a Creo Freestyle surface that can be easily solidified. This is especially important when optimizing parts for 3D printing.

We’d love to show you this Creo functionality live. So, after you watch the tip of the week video, head over to our contact page to request a demonstration.

Augmented Reality (AR) is a powerful tool used for design reviews, collaboration, and communicating design intent. The AR functionality built into every seat of Creo makes it easier for CAD users to share design info with colleagues, suppliers, customers, and manufacturing partners in a rich, immersive way.

First of all, why use Creo?

PTC Creo, formerly Pro/ENGINEER, is a product design software used by manufacturers for mechanical engineering, design and manufacturing. Creo supports designers from initial concept to design, simulation, and analysis. This CAD tool offers industry-leading capabilities, augmented reality (AR), and the ability to capitalize on the potential of the Internet of Things (IoT) – which enables users to produce better products, more efficiently, and at a lower cost.

Here’s a few examples of how you can benefit from the ability to rapidly create, publish, and share AR experiences directly from Creo.

Creo AR is fundamentally changing the way product stakeholders outside of engineering consume and leverage product data.

Common industry challenges and how to fix them

Share augmented reality experiences

Challenge: You need to quickly, efficiently, and safely get feedback for a design review from a supplier or vendor.

Preparing and packaging models so that people can see them for distribution and review can be a challenge. Engineers typically go through a process of saving a copy the files and keeping track of drawings, assembly, and parts with a risk of compromising intellectual property in the process.

Solution: Creo AR allows you to rapidly define and publish AR experiences that can be distributed instantly only to those who have permission to view it.

Visualize augmented reality experiences

Challenge: You’re unable to convey the size and scale of your design.

It’s difficult to visualize a design if it’s behind a computer screen or you don’t have the means to meet up and physically see the prototype. Engineers can spend a lot of time and money on creating multiple design drafts and prototyping for a short review feedback that could end up relaying to them that more changes need to be made.

Solution: Creo AR allows for immersive design data with full context and scale so that you can interact, explore, and engage with design data.

Creo AR Design Share Extension

The Creo AR Design Share extension allows you to create and manage more augmented reality experiences. The extension allows you to fully control the authoring and accessibility of your company’s AR experiences which protects your intellectual property by preventing access to critical CAD data.

The first 5 AR experiences you create within Creo are free. After that you can purchase the ‘Enterprise package’ which allows you to create 50 models, or the ‘Individual package’ which allows you to create 10 models. Purchasing one of the packages for the Creo AR Design Share extension will also give you permanent shelf life (versus 6 months free) and the administrative control to add and remove authors and viewers as well as add and delete AR experiences.

The value of augmented reality across the Enterprise

Augmented reality goes beyond the ‘cool’ factor. Organizations can make money with the value that AR brings to design, manufacture, selling, service, training, and operations. Talk to our Smart Connected Enterprise experts to learn more about augmented reality.

The rapid development of technology has transformed traditional modeling methodologies and provided new ways to deliver digital 3D models and product data. Computer-aided design (CAD) now gives users the tools used in all stages of product development from concept development to final presentation. Not only are the products changing with technology advances, the tools we use to design the products are changing too.

So how exactly is augmented reality changing the way you do your work? Here are 3 ways Augmented Reality is reinventing your design process.

AR makes your workspace way more flexible

You won’t have to be constrained to your desk to design products anymore. AR allows you to take your design beyond where you traditionally have done the bulk of your work. With the help of smart glasses, tablets, and mobile phones, you can design, and experience your designs anywhere you want whether it’s at your desk, in a conference room, or on a shop floor.

AR allows you to fully conceptualize designs

Digitally generated 3D models created within CAD software have a limitation – the rendering of the design is still stuck inside of a flat screen. Augmented reality allows you to fully conceptualize designs when they’re superimposed on the physical world. Augmented reality allows you to sit inside your design as you’re creating it – enhancing engineers’ ability to evaluate and improve designs. This lets you fully appreciate characteristics of a design at full, partial, or expanded scale in its intended setting.

AR reduces time and money spent on prototyping

Augmented reality gives designers and engineers the ability to view accurate representations of finished products in real-world scenarios without expensive prototypes. It eliminates the constant need to build multiple and costly prototypes because you’re able to see any design flaws in a half virtual, half physical world. By the time you’re ready to send your draft to a 3D printer or manufacturer, you’re already very confident in your design.

If you’re not already using AR in your design process, it probably won’t be long before you are. Companies like PTC are leading the way to innovation and new design processes by integrating Augmented Reality (AR) capabilities into their CAD software, Creo Parametric. Creo AR allows you to rapidly create AR experiences directly from Creo, easily manage and control viewer access, rapidly distribute and share AR experiences, and effectively communicate and collaborate design information.

Start creating, publishing, and sharing augmented reality experiences with Creo AR – download the datasheet to learn more.

On March 19th, 2018, PTC released the newest version of Creo Parametric – Creo 5.0. It brought with it new functionality and tools to improve design and help engineers and designers bring the physical and digital worlds together with augmented reality (AR) and smart, connected design.

“Product design is fundamentally changing, and Creo continues to evolve to meet the needs of our customers. With Creo, companies can go from the earliest phases of design to a smart, connected product,” said Brian Thompson, Senior Vice President, CAD Segment, PTC. “Improved functionality and new capabilities, like additive manufacturing, set Creo apart, and give companies a true competitive edge all the way from concept to manufacturing.”

The release includes advanced AR capabilities that ease the beginning stages of your product design process. Watch the EAC’s tip of the week on creating AR experiences from Creo here. The newest additions also provide designers and engineers with the tools to increase productivity, improve optimization, and get products to the market faster. So what’s new in Creo 5.0?

Subscription-Only Pricing & Annual Releases

Creo 5.0 and all future releases will only be available as a subscription. Unlike previous releases, there is no perpetual-license pricing available for new Creo Parametric seats. Ask an EAC representative about the current Reactivate Program to move to new Creo versions and packages at up to 23% off the list price of a new subscription license.

In October of 2017, Paul Sagar, VP of Product Management, Creo, announced the new annual release schedule for Creo software. The announcement showcased that going forward, PTC will release their CAD software each year to keep their customers up-to-date with the newest technology.

Creo 5.0 New Capabilities & Extensions

Topology Optimization Extension

Often times it’s a challenge to get past barriers to innovation with new physical designs due to already existing designs and practices. The new Creo Topology Optimization Extension automatically creates optimized parametric geometry based on a defined set of objectives and constraints. It’s a huge time-saver. The extension accelerates innovation without the limitations of existing designs and thought processes. It helps create improved designs without the over-engineering, additional weight, and additional material found in some designs.

Additive and Subtractive Manufacturing for metal 3D printing

Creo 4.0 enabled users to design optimize, and additively manufacture parts without the need to use multiple softwares – but now the Creo Additive Manufacturing Plus Extension for Materialise in Creo 5.0 extends support for metal 3D printing. New tools in the extension help generate and optimize custom support structures and weight/material saving lattices.

Mold Machining Extension

The new Creo Mold Machining Extension provides dedicated high-speed machining capabilities optimized for the creation of molds, tools, dies, electrodes, and prototype machining. These new capabilities can be used in complex machine designs to generate optimized design paths.

Creo Flow Analysis Extension

The Creo Flow Analysis Extension is a computational fluid dynamics (CFD) solution allows users to integrate analysis early and often to understand product functions and performance. The extension allows designers and engineers easily and quickly simulate fluid flow directly within Creo.

Productivity Improvements

Creo 5.0 includes many productivity enhancements such as an improved user interface, geometry creation with sketch regions, subdivisional modeling, surfacing, sheet metal tools, and volume helical sweeps.

Creo 5.0 also offers the Creo Collaboration Extension for Autodesk Inventor to help organizations consolidate onto a single CAD system and work with even more vendors/suppliers.

This reduces cost and effort associated with maintaining multiple systems and enables better collaboration throughout an enterprise.

Bring your design process to the next level with Creo 5.0.