- Reuse and instrument released designs

- Embed sensors into new designs

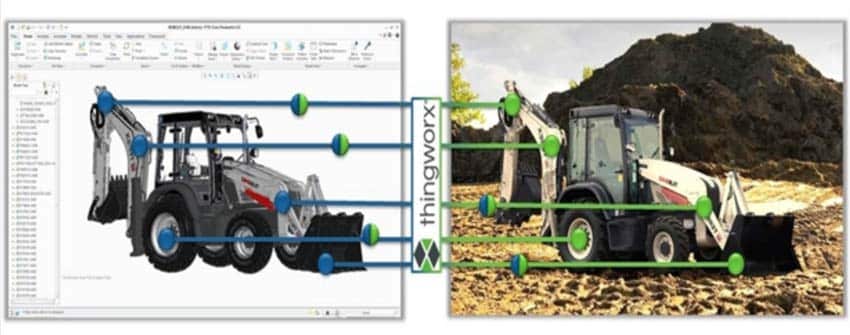

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

These days product data is everywhere. Everyone seems to collect it, have a lot of it, but the question remains; how exactly can you ensure your organization’s product data is being put to good use?

It’s time to take your product development one step further by providing role-based data access, connecting your enterprise systems, and learning how to make the most of your product data. I am going to explain exactly how easy that is to do.

The current state of product data

Companies today have many different roles that require access to product data. This may include people outside of the typical roles of which you may be thinking.

Departments such as engineering, manufacturing, that’s a given, but expand your thinking to include operations, purchasing, and marketing. They all need data access in order to edit and consume information. Think about sourcing…I’ll stop there, but you get the idea.

Let’s focus on the engineering department for a moment.

People could be involved from the mechanical side, the electrical side, or even a quality standpoint. Beyond that, people need to either contribute or consume information that could include manufacturing, service, sales, and more.

Product data game-changers

Product data silos limit productivity – PTC & EAC have the answer.

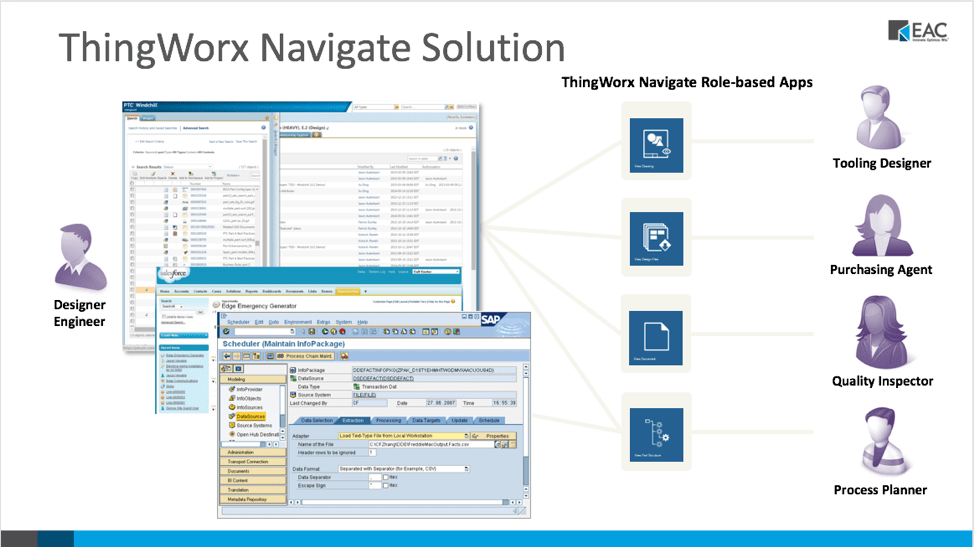

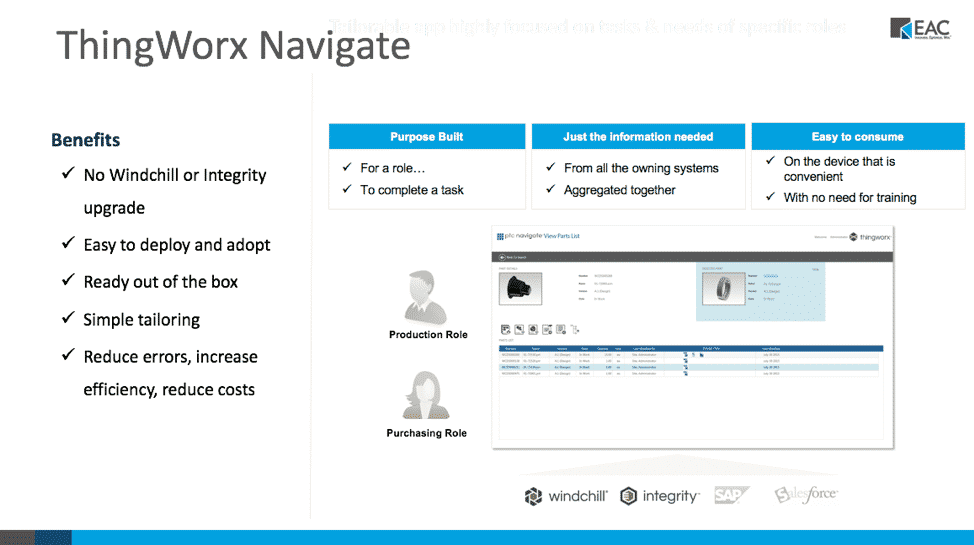

PTC ThingWorx Navigate was designed to address data accessibility problems by providing simple role-based apps that deliver just the right information to different groups (or departments) in the way that they need

When non-engineering colleagues need access to vital information, they typically interrupt an engineer or designer with a request. ThingWorx Navigate eliminates that distraction and “double-billing.” Through role or task-based self-service applications, data can be securely shared with a team. That way non-expert teams can use a simplified user interface to access the product data they need, right when they need it.

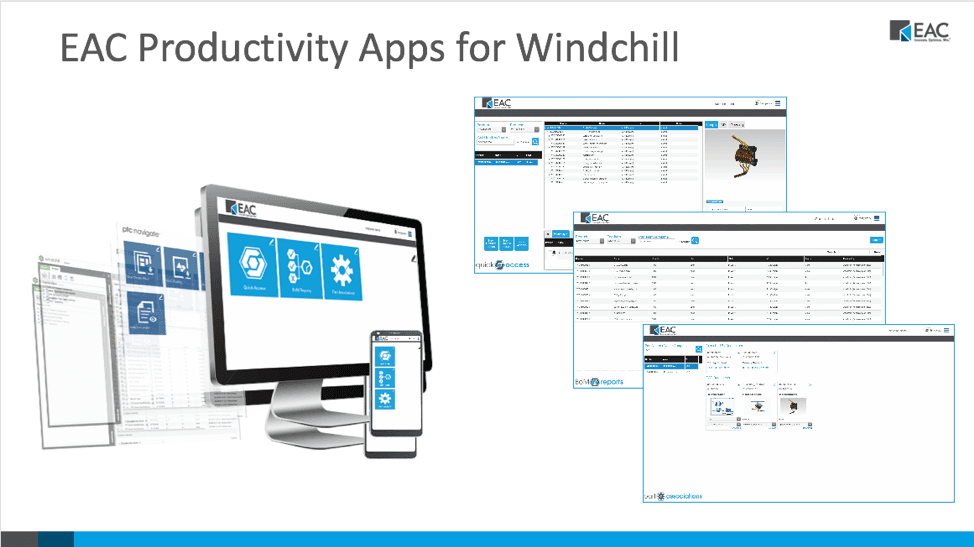

To help accelerate product development processes and take product data even further, our company (EAC Product Development Solutions) has also created what we call EAC Productivity Apps that work alongside ThingWorx Navigate apps.

So what’s the difference between ThingWorx, ThingWorx Navigate and our EAC Productivity apps?

This is a great question- I am going to try and paint the picture for you.

First, it’s important that you understand what ThingWorx is and how it is different from ThingWorx Navigate.

ThingWorx is the proper name of PTC’s Internet of Things (IoT) platform comprised of 5 components; foundation, industrial connectivity, analytics, studio,

The foundation component is the heart of the ThingWorx loT platform used to make connections to ‘things’ which could be machines, products or software systems or pretty much anything with an IP address and a communications interface.

User interfaces to the data coming from these connections are displayed on websites called ‘mashups,’ created with ThingWorx foundation. You might know these perhaps as ‘data mashups’ or possibly as ‘data dashboards’. Simply put, Thingworx is the IoT platform that makes everything possible. (Here’s exactly what makes Thingworx the leading technology for industrial IoT)

Then you have ThingWorx Navigate.

ThingWorx Navigate is the proper name of PTC’s applications that

ThingWorx Navigate Apps use a Windchill (PLM) connector to extract product data for presentation to Windchill Product Lifecycle Management users.

Fundamentally, ThingWorx Navigate Apps are all simply data and product information mashups created with ThingWorx. With ThingWorx Navigate you receive out-of-the-box apps that are instantly ready to be used with your PLM system. The idea behind these product lifecycle management apps is to ensure users can capture the complete functionality of their PLM (product lifecycle management) investment.

ThingWorx Navigate PLM Apps include:

View Design Files – A design file would be a format of a file that isn’t the native CAD format. This could be a staph or Induce or perhaps a 3D PDF

View Drawing – Allows you to look at just drawings. This application pulls drawings from your Windchill PLM system.

View Part Properties – This feature allows you to look at part properties- as if you were hitting the ‘Information button’ next to a file.

View Parts List – Allows you to look at bills of Materials (BOMs)

View Part Structure– With the View Part Structure App, ThingWorx is actually going into PDMLink and showing different aspects of a specific part instead of different ways of going at it (such as having to open several different tabs to get information). Using this application, you can get all your information together on one page. This feature also includes capabilities that cross-highlight part structures within your product. For instance, you could select a component and it would highlight that part and create a hyperlink that allows you to directly look at that specific part. This feature essentially creates a mash-up that takes information from different places inside of Windchill PDMLink and brings them together putting them on one screen, allowing you to have all your information at your fingertips.

View Document & View Document Structure

If you would like to learn more about ThingWorx Navigate technology or if you have any questions, you can always request to talk with Thingworx Navigate specialists here.

PLM Applications created by EAC

Our EAC Productivity Apps (also known as product lifecycle applications)

They allow departments to access content and perform common tasks through a very simple interface, versus having to use a complex product lifecycle management system (PLM) or Enterprise Resource Planning (ERP) system.

PTC Navigate Apps vs. EAC Productivity Apps

Our EAC Productivity Apps provide capabilities beyond that of the out of the box ThingWorx Navigate apps.

In short, ThingWorx Navigate applications allow you to securely access and present role-specific data from your Windchill system. They provide all of the power of a Product Lifecycle Management (PLM) system to someone who is not familiar with its ins-and-outs of product data management.

EAC Productivity Apps take it a step further by taking the underlying technology of ThingWorx Navigate, and the ability to get at the information in the PLM system and create even more complete applications that really give individuals instantaneous access to the information and product data they need to do their job. EAC’s PLM applications are created using PTC’s ThingWorx IoT platform, however, they can run independently of ThingWorx Navigate.

These apps are unique to EAC.

While built using the same ThingWorx foundation, ADK and [Windchill connector], they have their own look, feel and functionality. These mashups are packaged and sold together as a collection. EAC Productivity Apps created for Windchill promote user adoption and amplify the return on the investment you’ve made in your Windchill system, as well as extending role-based visibility into relevant product data and the impact PLM has on your organization.

Take your product data further with EAC Productivity Apps

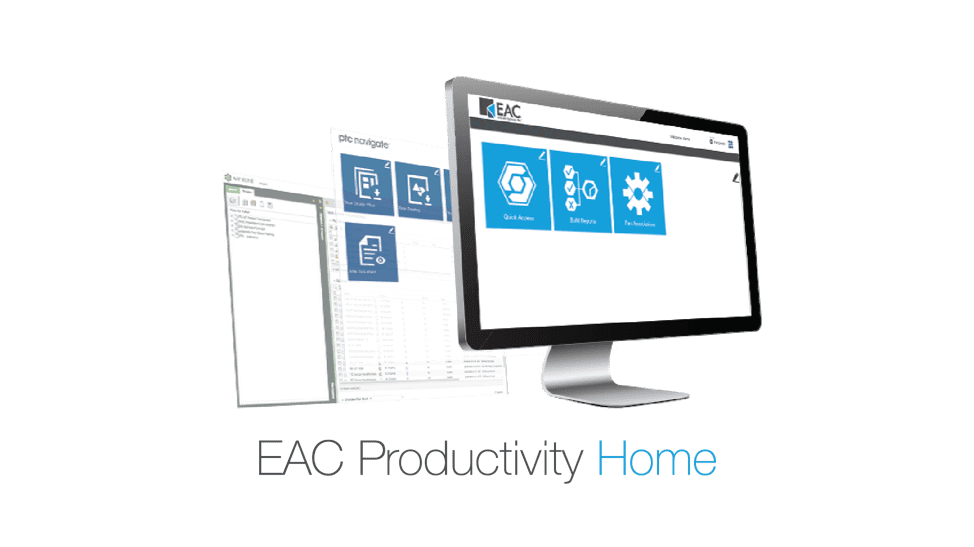

Every subscription of EAC Productivity Apps includes free access to EAC Productivity Home. EAC Productivity Home is a proprietary framework, or launcher, for ThingWorx Navigate applications.

It sits on top of Windchill and

The EAC Productivity App, Quick Search, provides a simple way for users to find content in Windchill. It removes the need for users to apply an understanding of how Windchill objects are related in order to find the information needed to do their job.

The Quick Search PLM application also allows users to search for components and retrieve information and file formats. For instance, if you were to grab a drive system and do a quick search, it’s going to find product information such as parts, EMP like documents, CAD files and more. See EAC Productivity Application Quick Search in action here.

You can also learn more about the Quick Search features in this brochure.

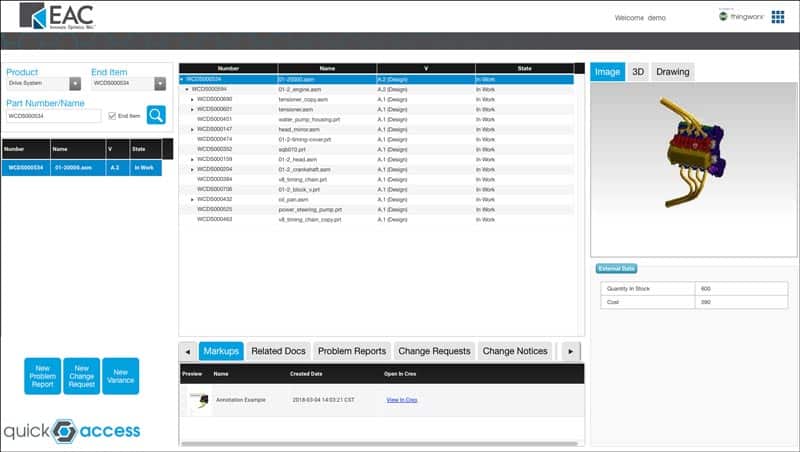

The Quick Access EAC Productivity Application streamlines access to critical and select data sets. Simplifies downstream users feeding critical quality information back to engineering with minimal effort.

This EAC Productivity App allows downstream users to feed critical quality information back to engineering with minimal effort. The simplified interface and consolidated task workflows help users easily submit new problem reports, new change requests, and new variances.

For instance, you could select a component (such as a product), pick its name (the end item number), search for it, and you would get straight to assemblies. With the use of Quick Access users can easily submit new problem reports, change requests, variances and more.

You can learn more about Quick Access features in this brochure.

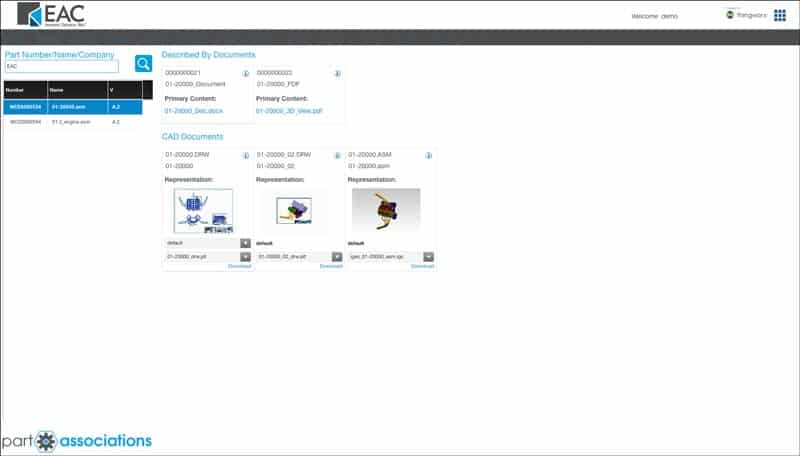

The Part Associations EAC application provides a “shortcut” for non-CAD users to access critical files and documentation associated with designs like drawings, parts, assemblies, and other documents associated with CAD files and part data.

You can learn more about Part Association features in this brochure.

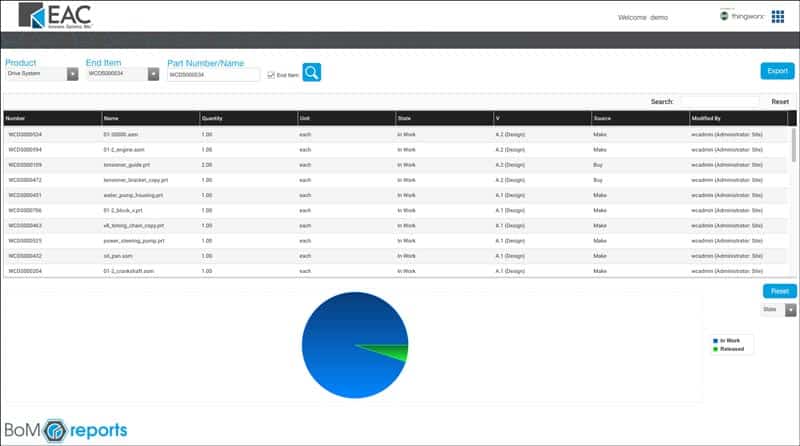

BoM Reports App provides a visual representation of cost

This EAC Productivity App allows users to quickly assess a Bill of Material and ensure projects stay on-time and on-track. The simplified view helps ensure products are built with the appropriate design iterations. With the use of BoM Reports users can easily see BoMs, lists of unreleased parts, parts that have been created or modified by specific users and more.

This app allows users to see the progress of a bill of materials, and apply filters to focus on parts that are not yet released. It is also useful for viewing all of the “make” parts or “buy” parts in a given BoM, or all parts created/modified by a particular user.

Get better access to your product data

See all the features of EAC P

We tend to operate our businesses like we’re playing a game of telephone…and it’s costing us all money.

You don’t have to be a genius to know that within many companies’ sales, marketing, and R&D teams serve separate functions. With different goals, targets and initiatives these teams tend to collaborate among themselves using the same system of record.

For example, within the same company, a department may rely on Product Lifecycle Management (PLM) systems while others may depend on Enterprise Resource Planning (ERP), Manufacturing Execution System data (MES), and Quality Management Systems (QMS).

Marketing, Management, Purchasing, Engineering, Technical Publications and manufacturing all need to operate off product designs and Bill of Materials (BOM), but while doing so people are likely to interrupt engineering to get information.

With this information they ask different questions, have different intentions, and speak different departmental languages.

The reality is; this inaccessible data is about the same product that happens to be housed in a system you can’t normally access.

By resorting to these misaligned processes, we end up operating on data without its entire context, therefore we lose productivity to requests for data and the switching costs of changing tasks.

Besides, these interruptions are generally counterproductive, especially when you’re working on one task and you’re interrupted regarding a completely different topic.

Without a single means to bridge these systems, your company is missing out on valuable information, time savings, and productivity.

We live in a world where siloed departmental communication doesn’t need to be the norm, after all technology is just about everywhere!

By integrating your critical data into a centralized location, your organization will increase visibility, and achieve better, more informed business decisions.

With technology that exists today, your separate departments can pull data from multiple systems into easy role-based dashboards, providing greater visibility and enhanced analysis.

The result is a rapid way for your team to get data from the vast data pool within your organization, and access it in an easy to consume space.

One of the ways we transform the way companies design, manufacture, connect, and service their products is by value stream mapping ‘Product Development Systems’ and looking for ways to ensure people have access to the information they need when they need it.

Tools like Thingworx Navigate, for companies invested in PTC’s Windchill solution, or the standard Thingworx platform and PLM Apps for those that aren’t, are helping companies pull information from different departments, systems, vendors, etc. to make sure every role has a simplified view of the information they need, when they need it, without slowing down any other departments.

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

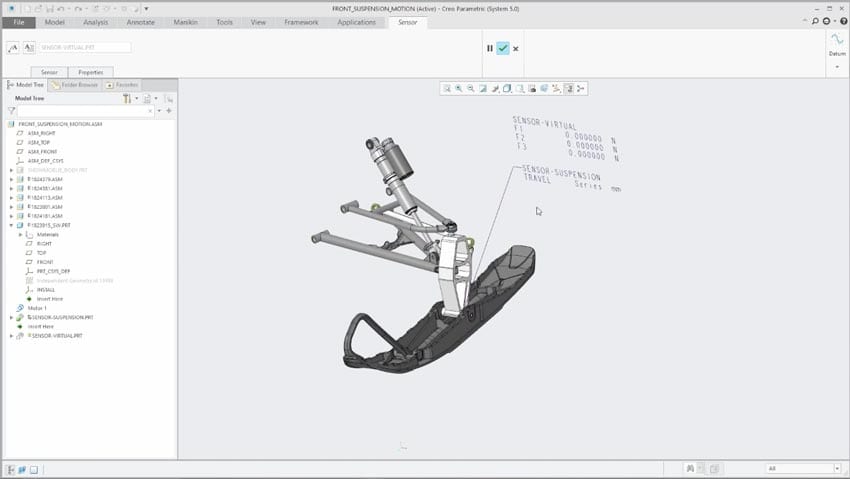

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.

Smart connected operations are transforming companies and changing the way we do business.

Imagine if your company was able to take advantage of data that revealed existing and future problems, and allowed your team to make drastic improvements by completing predictive maintenance and service.

Business decisions can no longer be reactive. You need to be proactive — Here’s how smart connected operations could ‘revolutionize’ the way you do business.

Smart connected operations help businesses make faster decisions

What helps a company make fast, highly informed decisions? Data.

Smart connected operations allow information to be collected from multiple sources, assets, facilities, and even vendors. This connectivity allows data to be collected and analyzed to inform decision-making and enable teams to make faster decisions.

Smart connected operations help businesses increase operational performance

Smart connected operations can help your business monitor and track asset viability, ultimately allowing your company to reduce downtime, improve design, and improve utilization.

Data from connected assets, in collaboration with other enterprise systems, can provide not previously possible visibility and automation across organizations.

For example, product data flowing through a CRM system can also be sent to billing or into a supply chain management system— helping to eliminate error-prone manual steps and providing new sales opportunities for things such as consumable replenishment or warranty renewals. (PTC)

Smart connected operations help businesses decrease lead time and increase product quality

The insight smart connected operations provide will help you improve and perfect your production processes.

By integrating smart technologies and processes, your organization can lower development costs, time-to-market, and improve your overall product quality.

Smart connected operations help businesses improve manufacturing responsiveness

A sensorized manufacturing floor let’s you monitor performance, in real-time, and provide valuable information to field service technicians and manufacturing floor managers.

Service responsiveness will be accelerated with remote monitoring, access, and complete management of your disparate systems through enabling smart connected operations within manufacturing.

Smart connected operations help businesses improve supply chain coordination

The new capabilities of smart, connected operations will alter every activity in the supply chain.

Your operational efficiency will increase exponentially if your organization reaps the benefits of integrating with other data, such as inventory locations, traffic patterns, commodity prices, and historical data repositories.

Smart connected operations help businesses reduce manufacturing IT costs

Smart connected operations use digital interfaces that make it easier and less expensive to track the production process. These interfaces are less costly to apply and easier to modify than physical system controls. By integrating smart connected operations, your company will increase operation mobility, which in turn can reduce your manufacturing IT costs.

The sensors in smart connected operations also identify a need for service before the machine or product fails. These data analytics will drive previously unattainable efficiency improvements by providing predictive maintenance analytics and higher productivity levels.

With the help of predictive analytics, smart connected operations help organizations anticipate problems and take early action.

For example, your industrial machines would be remotely monitored and adjusted by end users during and beyond operation hours. They could even begin to manage themselves leveraging machine learning and predictive analytic engines.

The bottom line is that smart connected operations have begun to change business models, organizational structure, and manufacturing system architecture.

The development and the deployment of smart connected operations will be incremental, but the opportunity is here today.

What are you waiting for? It’s time to start capturing the time, dollars, production, and quality that smart connected operations can provide.