You can reduce time to market and cut costs by advancing your digital thread with PTC Windchill, the industry-leading Product Lifecycle Management (PLM) solution. Windchill consolidates data so that your team can work faster and more accurately so you can focus on product innovation.

See how Virnig Manufacturing uses PTC Windchill to change the way their data is delivered within their organization.

Business Initiatives

Located in Rice, Minnesota, Virnig Manufacturing has been designing and producing skid steer attachments for over 27 years. This family owned one-stop shop does all steps of the manufacturing process in-house: engineering, cutting raw materials, machining, welding, and painting the finished product. Virnig dominates the industry by offering high-quality skid steer attachments and continually innovates to maintain a strong competitive advantage in a challenging and competitive market.

Business Challenges

Virnig has grown exponentially in the last decade, prompting the on-boarding of more employees to keep up with the growth. The expanding workforce introduced a new challenge of organizing critical work documents. The process of finding documents every day began to inhibit productivity. The need for a file management system became obvious and critical.

Finding a solution became a top priority as Darin Virnig, Engineering and Production Manager, and his team found themselves taking on projects that required “more time in a day” to complete. Darin stated, “When there were just a few of us looking at files we weren’t quite as concerned about file management and having things get overwritten. But as we had more and more people working we all looked at each other and decided it was time to implement a file management system so that we didn’t start losing data or have it changed accidentally.” Prior to implementing a system, Darin and his team kept product content and design data in large red binders throughout the manufacturing facility. Engineers would leave their workstations to access folders in designated areas – sometimes on the other side of the manufacturing floor. Virnig was losing precious time to their paper-based processes. Darin needed to find a quicker way for his team to access data if he wanted to achieve maximum productivity on the shop floor.

Solutions

EAC Product Development Solutions (EAC) is an engineering and technology services company headquartered in Burnsville, MN. They provide product development solutions that transform the way small to medium sized companies design, manufacture, connect, and service their products. Virnig had partnered with EAC to implement PTC’s simulation software and trusted them with this new file management challenge. PTC is a global technology provider and the maker of tools such as Creo Parametric CAD software and the Windchill line of product lifecycle management solutions. “It was only logical to go with PTC products since we have been doing all of our modeling with their products,” says Darin.

The benefits of going paperless exceeded Virnig’s accuracy and collaboration goals, and provide an ancillary benefit of reducing the cost of paper and printing. The decision was made to implement Windchill, PTC’s product lifecycle management software to streamline operations and control files.

The Paperless Movement

Windchill PDM Essentials, PTC’s Product Data Management tool empowers companies to organize and manage their product content to improve access to accurate, timely product data. Darin and his team have implemented Windchill across their engineering and manufacturing facility with 10 different access points for each department on the shop floor. Darin chuckles as he talks about removing the now-unnecessary red binders, “we took away their file cabinets.” The new process didn’t require any paper documents on the floor – everything was now digitally stored in their workstation computers throughout the facility. The implementation prevented wasted time that was previously used to sort through red binders, and avoided the use of old, irrelevant information.

Darin talks about the success of the new data management system, “Paperless provides access on the floor which has increased accuracy and quality that will give us the competitive advantage we were looking for.” He describes how his team members used to take over 30 minutes a day searching for the data needed to complete a specific task. “It was a company initiative to go paperless in all areas to increase accuracy – the accuracy is where the cost savings would come in for us.” Going paperless has allowed Virnig to take advantage of that 30 minutes a day to add over 325 productive hours to their operation each year.

Learn more about PTC Windchill, contact us, download the case study, or watch the video.

Stephen Covey’s landmark book ‘The 7 Habits of Highly Effective People’ lists the 7th critical habit as “Sharpen the saw.” It references a parable of a lumberjack and a stranger. The woodsman is very busy cutting down trees. As he completes more and more work his effort increases and his productivity goes down because his saw dulls over time. The lumberjack, exhausted and cursing the labor, is approached by the stranger. “What’s the problem?” asks the stranger. “My saw is dull and won’t cut well” responds the lumberjack. “Why don’t you sharpen it?” asks the stranger. The lumberjack responds “What kind of question is that? Because I would have to stop sawing, and I’m very busy.” The stranger responds “But, if you sharpened your saw you could cut more efficiently than before. You could get even more work done.”

It’s important to sharpen our saw. We need to keep working to improve our knowledge base, approach, and overall situation. This may involve attending a training class, reading a book, mentoring and being mentored, or joining a peer group. I understand this can be difficult in the world of product development / engineering / design / manufacturing / and service. There is always pressure to get to market, get to the trade show, meet customer demands, etc.

Efficient engineering, design, manufacturing, and service requires efficient use of the supporting technologies for each role. Our training group consistently proves a return on our customer’s investment in training and development. That’s because technology keeps getting better. If you don’t know how to take advantage of the full functionality of your tools like PTC Creo, PTC Windchill, PTC Arbortext, and PTC Mathcad…you’re cutting with a dull saw.

We consistently schedule key PTC certified training classes and training courses that help people throughout organizations make the most of their technology. We deliver everything from Windchill Administrator courses to training classes for specific PTC Creo tools and functionality.

Do me a favor. Take time to sharpen your saw. A few days in a training course could save you hundreds of hours down the line. Take a look at the EAC Training Calendar. Maybe you’ll find the perfect PTC training course to put a new edge on your saw. Contact our training group to learn more about our training and mentoring delivery options (Like EACLive!) and full course catalogue. And check out this blog to learn more about how to select a PTC Training Course and Training Class provider.

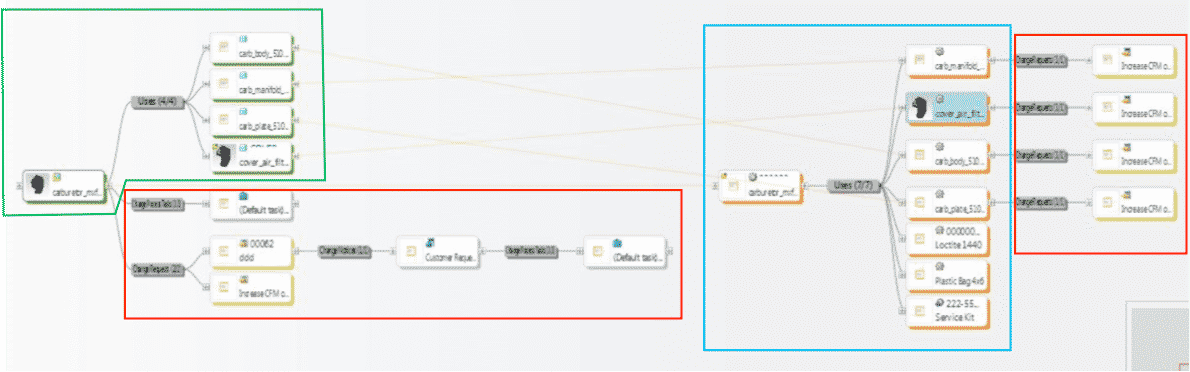

Part II – (You can read part 1 here) Evolving your BoM strategy, tools, and abilities. “EBoM vs. MBoM” transforms into “EBoM integrates with MBoM.” This integration includes associativity to one another, time saving tools, elimination of error prone manual steps & more.

Imagine eliminating the common disjointed processes, additional time, and error prone manual steps involved in the creation of downstream BoMs from Engineering into Manufacturing, Production and Service management.

Concepts & examples such as Manufacturing Bill of Materials (MBoM) are shown below, all under one system, integrated & associated, and created with a single click. Then they’re easily edited to meet downstream BoM needs.

BoM creation can be streamlined & improved by associatively creating downstream BoMs (S or M or other) and eventually, connecting them to your ERP system. For now, we’ll focus on the first step of this business transformation concept; the creation of the second, or downstream M or SBoM, starting with a simple EBoM example, created in minutes, and easily viewed & tracked.

Who should be involved in this topic at your company? Ideally, your Configuration Manager role should be leading or heavily involved in this process.

The starting point & tool is PTCs Windchill and your willingness to change & improve.

Once your CAD data is ready to check into Windchill, there is an option (check box) to auto-associate the EBoM to a downstream BoM such as an MBoM. It is a 1:1 relationship for starters. Options can branch out from here into many CM (Configuration Management) directions. Such as multi-level BoM management, uses, visualization and more.

Once created, you can manipulate & edit the default 1:1 downstream BoM to your needs; adding bulk items, manufacturing specific sub assemblies, (build throughs) even new service end items. You can also flatten out an EBoM to meet assembly or production needs. BoM items such as adhesive, lubricant, paint or coatings, packaging items, all things that typically are not on an EBoM, can and do belong on the M or SBoM.

If this fits your company’s needs? consider using Windchill’s auto-associate feature.

This article covers a couple examples. If this is not deep enough…here are even more tools to consider. Topics such as creating associated manufacturing instructions, work instructions, work plans and more. Change Management is shown as reference only, it is an optional element of Windchill for another blog.

There are many options to this topic, these are common examples that fit a lot of needs and is considered a starting point.

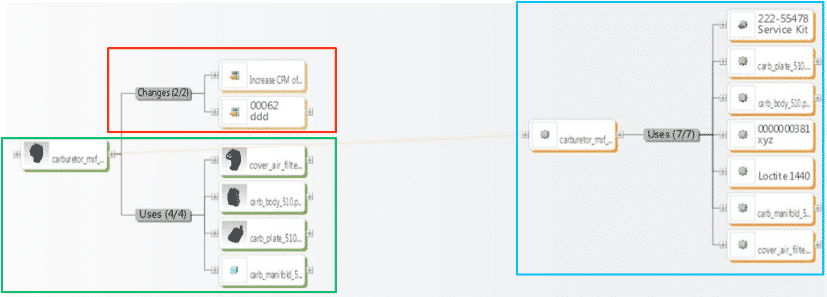

1stexample shows all BoM & change components all connected in one system vs. manually done in silo fashion, which is industry’s most common method today. These examples are shown in PTCs Windchill reference viewer tool, which ties all related objects into view for easy visibility with just a few clicks.

- 1. EBoM structure (highlighted in green)

- 2. Change requests, notices and tasks (highlighted in red)

- 3. MBoM structure (highlighted in blue) with their own, or connected Change Management Requests, Notices & Tasks

2ndexample shows an EBoM, SBoM (Service Kit in this example), with a saleable end item service kit, as well as components for service or manufacturing BoMs. It also shows Changes, these can also be created, edited, routed, approved or rejected, and even include the SBoM if need be.

Please connect with EAC to learn more, to discover your company’s transformation opportunities with an assessment, maybe see a demo, or attend a webinar. The goal is to help your company transform how you design, manufacture, connect to and service your products.

Windchill is a mission-critical enterprise system with multiple components and touch points across an entire enterprise. Because of this complexity, you might recognize the need for Windchill Managed Services.

EAC has created a managed services program for your Windchill system – The EAC Alliance Program. The Alliance Program provides PTC Windchill managed services such as Windchill administration and support.

Our team of expert system administrators help improve system performance, optimize server and license configurations, and maintain a stable PLM environment for your organization.

Here’s what customer’s see with our Windchill Managed Services and what you can expect.

Windchill Managed Services Percent of Uptime

95.1% of our EAC Alliance Program customers achieve 100% Windchill uptime. Our customers that do not have 100% Windchill uptime still maintain over 99% availability. This is an overall average of 99.95% or more uptime.

Windchill Managed Services Predictive Maintenance

Our Alliance program executes planned (weekly, monthly, etc) Windchill maintenance. Predictive maintenance is more efficient and the preferred approach to system maintenance. Roughly 1/4 of Alliance customers choose to implement PTC System Monitor (PSM) as a way to bolster EAC’s already rigorous proactive maintenance.

Speed/Performance of Windchill with Managed Services

100% of EAC’s Alliance Program customers see an improvement in the speed and performance of their Windchill system. Out of the box, Windchill leaves a lot of room for performance tuning and server optimization. Our EAC Alliance Program Team are skilled in analyzing and optimizing system resources to suit your individual needs

100% of EAC’s Alliance Program customers see an improvement in the speed and performance of their Windchill system. Out of the box, Windchill leaves a lot of room for performance tuning and server optimization. Our EAC Alliance Program Team are skilled in analyzing and optimizing system resources to suit your individual needs

Windchill Managed Services Security/Patches

100% of our EAC Alliance customers receive (or are notified) of patches. This way you can be assured that your system is running with maximum security at all times.

Want to learn more about what our EAC Alliance Program has to offer? Download our Alliance Program Brochure and check out the top 10 questions we get about our Windchill Managed Services.

Help us help you! We know your Windchill System is critical, that’s why we designed a program just for you.

Some estimate that 70% of companies do not regularly perform routine maintenance on their Windchill System. Were on a mission to change that.

In an effort to provide on-going technical support, business process consulting and adoption services; EAC offers the Windchill Alliance Program (Services). This is a service package intended to provide professional Windchill maintenance and administration services, regardless of a customer’s stage of adoption.

Our team of expert technicians will improve your system performance, optimize server and license configurations, and ultimately maintain a stable PLM environment for your organization.

After receiving your FREE Windchill System Checkup and becoming a customer, here’s what you will receive:

System and Application Administration

This includes everything from starting and stopping your Windchill environment to cleaning up unreferenced files and cache folders. Let our team do the busy work of monitoring and managing your system so you can get the most out of your Windchill investment.

Database Administration

The EAC Alliance team will review, restore, and analyze your database growth and performance. Our database administration covers anything and everything from network administration, security administration, and backup services. Put us in-charge of performing and verifying your scheduled system backups to ensure your system is running properly.

Business Administration

We will take care of all your Windchill business administration needs such as adding new roles, updating accounts, operating system maintenance, network administration, license usage reporting and more.

End-User Support

Our end user support consists of everything from help desk support, to advice on best practices, to user mentoring, to Alliance Program review meetings and more. We want to help you with all your system questions and needs.

Still want to learn more? Check out our article on the Top 10 Questions we get about our EAC Alliance Program.

Also, Here’s what customer’s see with our Windchill Managed Services and what you can expect as an EAC Alliance Customer!

Our goal is to help you increase your Windchill system uptime, eliminate corrupt workspaces, improve sluggish system performance, safeguard your security, and guarantee your system is up-to-date. Take a proactive approach to maintaining your Windchill environment today!

We have had a long-standing relationship with a local manufacturing company over the years and are proud to share their success story with the rest of the product development world. PTC Windchill, PTC’s PLM solution, helps Virnig Manufacturing go paperless, streamline operations, and save over 325 hours per year.

What stands out about this case is the fact that the company was able to reduce or eliminate paper trails in all departments in less than one month thanks to a single tool. Why is going paperless such a big deal? Companies go out of their way to eliminate unnecessary processes in order to operate at a maximum efficiency. Most companies will invest in a Product Lifecycle Management (PLM) system to streamline the flow of product data through the organization, improve quality and efficiency, and better manage their business. PLM systems organize a company’s product data in one place so there are no obstacles between departments and accurate product, manufacturing, and service information.

Virnig Manufacturing has been designing and producing skid steer attachments for over 27 years. Due to an expanding workforce over the years, Virnig faced a new challenge of organizing the over-flowing piles of critical work documents. Darin Virnig, Engineering and Production Manager, and his team kept all work documents in large red binders throughout the facility and in each department. Due to the recent growth and expansion of the business, Darin needed to find a file management solution.

Download the case study to see how Virnig Manufacturing is leveraging a right-sized PLM solution — PTC Windchill — to overcome some of their biggest challenges.

If you don’t have PLM in your organization at all, reach out to us. We have a team of experts ready to answer any questions you may have. They would love understand your situation and the benefits of implementing PLM in your organization.

Click above or watch the video here.