Let’s talk about how technical documentation impacts field service procedures, high costs of inaccurate technical information, the root causes of service failures, and how to achieve high field service productivity and effectiveness.

Many of the fundamental issues in service occur due to inaccurate service information and technical documentation that is difficult to understand.

We have all been in a situation, at least once, that involved failure to deliver a service as promised. Why? It’s because all brands and businesses make promises! But the truth is… service issues happen

When service fails to deliver on promises, or a buyer experiences poor customer service, the result almost always ends with lost customers, canceled subscriptions, and tarnished brand reputation.

The impact of a service failure can be devastating. Let’s talk about the root causes impacting service issues and failures

The impacts of service issues

The greatest influence on service almost always has to do with one thing; technical documentation. By technical documentation I am referring to tech pubs, standard operating procedure documents, service instructions, maintenance manuals, guides, work instructions, procedures, bulletins, etc.

I’m talking about anything and everything that is provided to help assist and guide service technicians. Many of the fundamental issues in service occur due to technical documentation, let’s talk about why.

Technical Documentation and Field Service

Today many field service and manufacturing organizations rely on traditional time-intensive methods to develop and deploy technical documentation such as service procedures, work instructions, guides, manuals, etc.

But the fact is – oftentimes the tech pubs, guides, and manuals that are created, aren’t even read (or in some cases even used) by field service representatives for which they were designed!

In addition, technician instruction manuals and documentation designed to be used in field service are often out-of-date. This is due to the high maintenance and distribution costs to create, maintain and produce continually up-to-date field service documentation.

This issue compounds as products become more and more complex in response to ever increasing customer demands for innovation and customization.

This rise in complex products has resulted in complex service and maintenance procedures, affecting and influencing inaccuracies in technical writing and documentation. As the demand for complex maintenance and service procedures increase, technician efficiency decreases due to more time being spent searching for the correct service information in a format that can be used on the field. This often results in repair and maintenance delays.

When service technicians encounter unfamiliar problems and don’t have reliable service information to solve a problem, the need for repeat service visits increases. There are many major negative consequences from these situations.

For example, a customer might experience equipment downtime. This downtime impacts both the service provider, as it inflates the cost of service, as well as the customer, as they lose productivity.

The high costs of inefficient field service

For you, as a service provider, the consequences of poor service information, complex products, and poor technician efficiency can drastically impact your costs of service in a number of ways.

For starters, let’s assume you work with service contracts. Service contracts often contain elements such as equipment up-time clauses. In the case you were to unintentionally breach one of these ‘set clauses’, it’s fair to assume the organization would face undesirable penalties and costs.

Take a deep breath. All is not lost. The added costs from inefficient service strategies are completely avoidable!

Repeat field service visits also drastically increase business costs. Multiple repeat visits to service products quickly increase costs and become very expensive. This is why many organizations seek to avoid repeat service visits at all cost.

A rarely considered cost-driver for service stems from difficulties comprehending poorly written, inaccessible, and out-of-date technical documentation.

When service technicians are unable to easily identify which spare parts are required, they often order multiple parts in hope that one will be correct. This results in high part returns, and handling costs. Not to mention, the need to hold more parts in stock from inflated orders (the bull whip effect), also affects parts inventory.

The skills gap is also increasing the cost of inefficient service.

“Faced with continuing economic expansion and retirement of baby boomers, the US manufacturing industry is looking at a potential shortage of 2.4 million workers in the next decade.” – 2018 Deloitte & The Manufacturing Institute skills gap study

To put it in perspective, a large portion of our workforce is approaching retirement soon. This is causing the skills gap to widen. With the loss of tribal knowledge, access to consumable expert knowledge becomes increasingly necessary.

New and inexperienced technicians have repeat service visits which cause an organization to face higher training costs, while overburdened experienced staff members are forced to train and pick up the slack for newer employees.

All of these things impact customer satisfaction. These conditions damage service reputations for both an organizations product, as well as, service contracts. Most importantly, all of these scenarios impact an organizations ability to retain customers and garner repeat business.

Sometimes you need to break down the barriers between product development and operations.

How to gain high service productivity and effectiveness

In order to obtain high technician productivity and effectiveness you must re-evaluate your service methods and procedures

Increase technician comprehension with accurate AR work instructions

To increase technician comprehension, look into concepts to create accurate, in-context augmented reality (AR) work instructions that overlay digital information onto a physical product.

Establish accurate part identification

Consider implementing accurate AR experiences so part identification, replacement and ordering are easy and accurate.

Enable remote real-time work instructions

Enable expert technicians to give remote, real-time guidance on physical objects using assisted reality tools like Vuforia Chalk.

All of these help service organizations create a more flexible, agile, workforce. These changes result in increased equipment uptime and productivity. They result in happier customers and more empowered workers.

Most importantly – you can start implementing these benefits today. All the technology currently exists. We would love to work with you and your organization to understand your service operations goals and map a path forward.

Augmented Reality (AR) and Assisted Reality for digital work instructions have become a growth driver, or at least consideration, for many industries.

Yet moving everything from paper or ‘digital hard-copy’ to digital AR experiences seems to be a daunting task for large and small organizations alike.

The truth is, there are many ways to incorporate augmented reality into service, but many of these can disrupt current processes and be a challenge to implement.

This is why, our company (EAC Product Development Solutions), developed and created an easier way to make service information more accurate, relevant and accessible.

It allows you to easily deliver the content behind AR instructions, manuals, and guides to digital devices such as tablets, head-mounted displays, or cell phones.

Implementing AR for service should be easy. That is why we created a better way.

The tool is called AR Instruct – It easily connects traditional technical publication content to the AR world.

Digital Work Instructions & AR Instruct

AR Instruct enables “hands-free” execution of work instructions using the latest immersive technology including: Augmented Reality, Assisted Reality, and Mixed Reality.

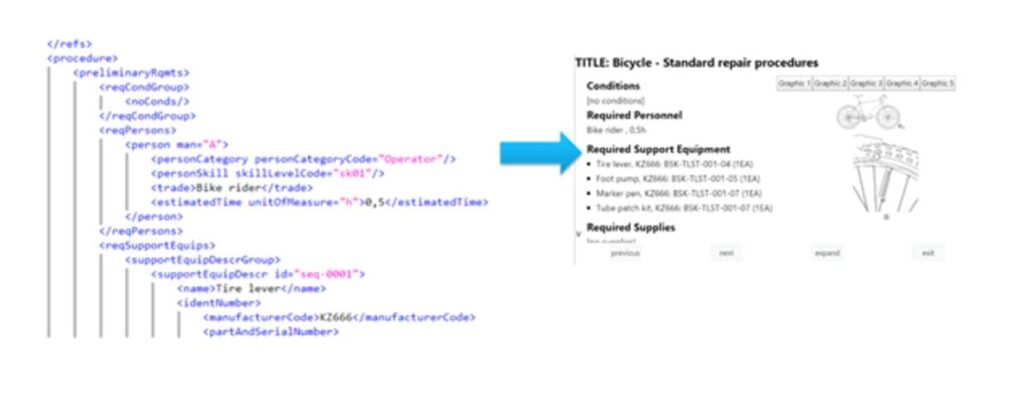

Our AR solution works as an AR publishing engine that repurposes existing S1000D, Arbortext, or XML, technical publication content and simplifies the transition to hands-free and mobile paperless instructions.

The best part? AR Instruct requires no content re-authoring and no content rebuilding. It’s really that easy.

AR Instruct can even dynamically publish up-to-date work instructions from the latest document revision on your server. This will ensure accuracy, compliance, and quality.

Watch the video below to get a quick and easy introduction to AR Instruct.

How does AR Instruct work?

A Service Engineer scans a work order QR code to locate relevant service procedures.

Our AR publishing engine, AR Instruct, retrieves XML content and dynamically formats it for AR viewing. This requires no manual publishing at all.

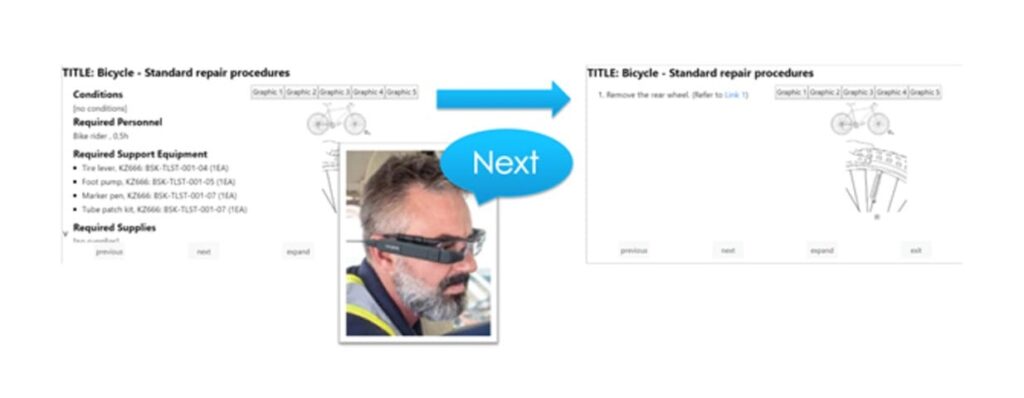

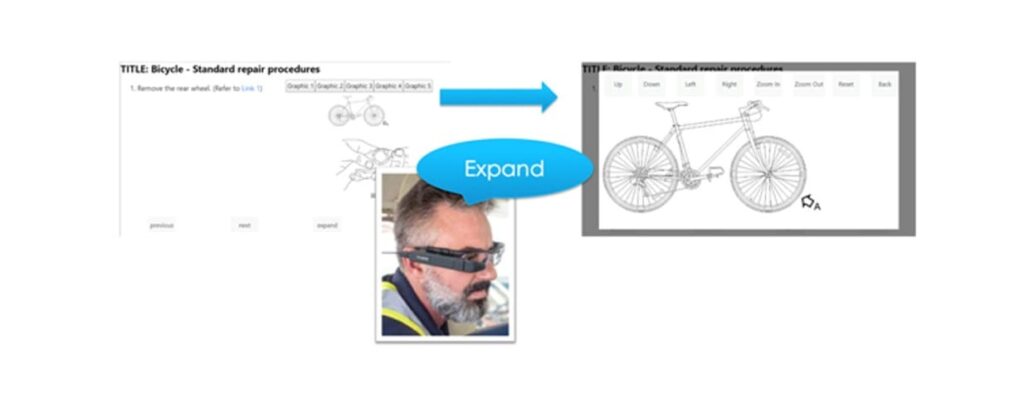

Using a digital device like a Vuzix or RealWear, the service engineer can navigate the AR content hands-free with voice commands.

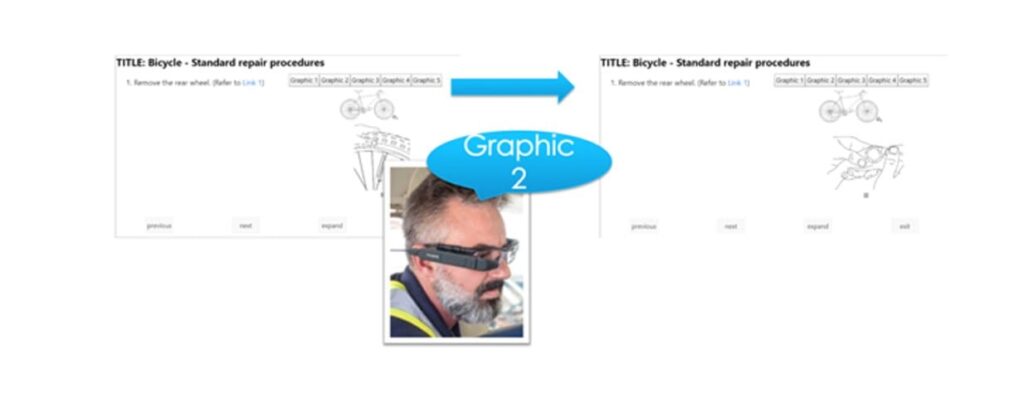

The Service Engineer can inspect each associated technical graphic related to the product.

The Service Engineer can also expand any technical graphic or content for enhanced viewing.

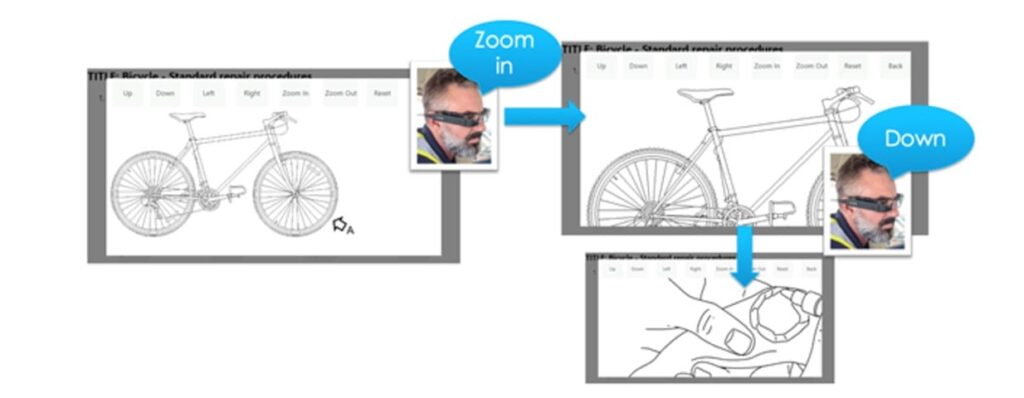

With the AR Instruct graphic viewer, the Service Engineer can pan and zoom any image by using voice commands. All buttons he or she sees are “readable” as voice commands.

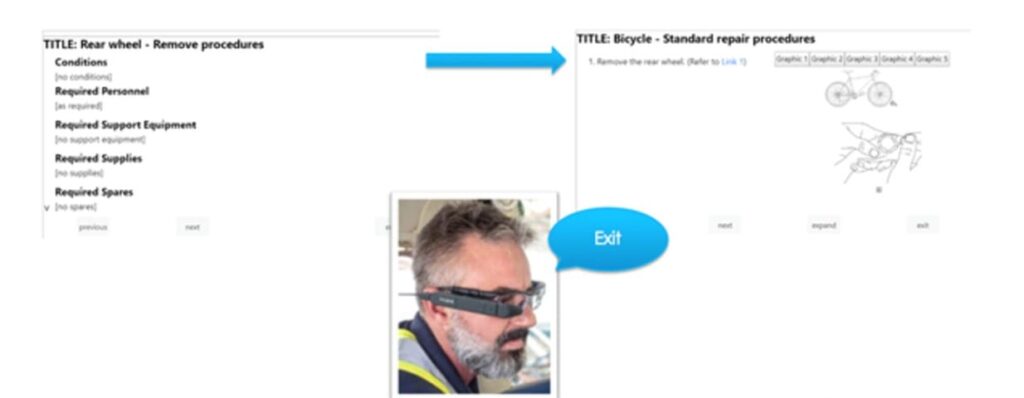

Using voice commands, the Service Engineer can navigate links to cross-referenced steps or procedures.

Once the Service Engineer is done with the cross-referenced content, he or she would be able to return to where they left off in the original service procedure.

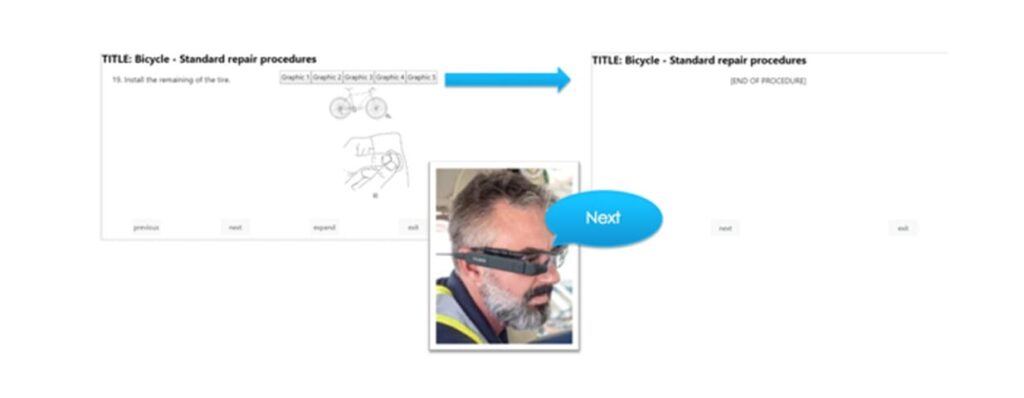

When all steps are complete, the AR Instruct software notifies the Service Engineer that the procedure is done and all steps are recorded as complete.

The Service Engineer exits back to the bar code scanner to begin a new work order or procedure.

It’s really that easy.

If you are looking to improve operational efficiency, appeal to the modern workforce, execute service checklists 3-5% faster and enable greater compliance and quality assurance over completed work instructions, AR Instruct is exactly what you need.

Want to see AR Instruct for yourself? Request a Demo today.

If your organization creates service information, work instructions, installation operator guides, user guides, technical instructions, service manuals, or even service procedure bulletins – it’s time to rethink your process.

Let’s talk about how to make your service information accurate, relevant and accessible.

Defects in products happen, but in the case that a product needs to be taken apart- it’s important to do it the right way. This is especially true with today’s advanced complex products.

This is why organizations often don’t question why they’re managing mountains of paper-based technical publications. But what happens when a service call involves the use of particular tools that aren’t quite outlined in a service procedure manual?

Or when field circumstances turn out to be different than the initial service order and the correct manual may not have made it into a technician’s vehicle?

What happens when technical publications designed to guide service are no longer relevant due to product or tool changes? Despite best efforts – service, installation, and operation problems arise. These problems cause worker confusion, dissatisfied customers, and business risk.

Providing information that no longer applies to specific products forces operators to troubleshoot challenges based on assumptions and experience – or worse – inexperience. Paper-based and locally stored procedures, instructions, and guidelines also have a tendency to make work instructions difficult to find.

If your procedure documentation guidelines are disconnected, they are only hurting you.

The good news is, with the help of simple technology, any organization has an opportunity to rethink their service information. There has never been a better time to make service information accurate, relevant, and easily accessible.

The solution? Interactive digital work instructions.

How to make service information accurate

You might be surprised, but as a matter of fact, the first step towards achieving accurate service information involves using the content (such as Tech Pubs, Arbortext, DITA, XML, Images, etc.) that your organization has already created. Evaluate the current service information processes your organization has in place. For instance, you might currently be using paper documentation.

What’s the problem with paper documentation?

Once your documents are committed to paper alone, you can no longer assure their ongoing accuracy. The underlying information could have changed right after it was printed! Your information should (most definitely) include the latest version of technical publications and content (such as Creo Illustrate, Windchill, Service Information Manager, InDesign, FrameMaker, Oxygen, etc.) that you already have without the need for added latency or work for authoring, styling, and publishing.

When you’re in a digital work instruction environment, that environment is set up to draw from the most accurate up-to-date information available on your system. This is why the best possible way to ensure the accuracy of your service information is to move away from paper workflows and go to digital work instructions – instantaneous access, up-to-date information.

How to make service information relevant

The best way to ensure that your service information is relevant is by connecting your technical publications back to your engineering and manufacturing content creators.

What do we mean by that?

Your work instructions, service manuals, operation guides, and bulletins all come from files you have on hand. So why shouldn’t they directly connect to and show operators and technicians accurate and relevant information about what they do?!

Furthermore, if your current service processes involve the need to find and locate product information before your technicians start the job, you end up losing valuable time.

It’s time to change that.

The way to make your service information more relevant is to have your instructions take your technicians down a specific product path. Using visual work instructions will allow your service teams to get specific information and insights that directly pertain to what they need.

By implementing technology that can cross-reference technical publication content, you can be sure your service information will always be relevant no matter the task.

The technology available today even has features like ‘work process selects’, to route directly to the correct tech pub content. Even better, it also has the ability to navigate to cross-referenced content such as DITA, XML files, images and more!

Simple solutions on the market today can even provide service technicians and operators with the ability to immediately start on a service task. With the help of technology, such as a digital device or a handsfree headset, service technicians can instantly receive relevant work instructions at their fingertips… or eyeballs… by simply scanning a barcode.

Your service information should be accurate and timely, and the best way to make that possible is by directly connecting all the files you currently have! It’s that simple.

How to make service information accessible

Making service information more accessible has everything to do with the use of digital devices such as mobile or wearable devices.

By using mobile or wearable devices, workers have the ability to instantly connect directly to work processes and even existing tech pub source content. Every organization has the ability to make service info easily accessible to the extent that the company wants.

For instance, you can easily make any information accessible and relevant now with a connected Industrial IoT environment. By using Wi-Fi and cellular connections, technicians have the ability to connect online to whatever the most relevant information is.

Your path to better service information

Please contact us to see how Industrial AR can be used to connect and reuse existing technical publications and content. We have the know-how, technology, and team to help you take your digital transformation to the next level, decrease service and manufacturing errors, and improve the way you distribute technical information.

Watch this video to see EAC’s solution for converting work instructions to digital AR experiences with AR Instruct.

The stakes are high and, as technology is making the world ‘smaller’, competition is growing at a furious rate. Your enterprise needs to stay on-point at all times and deliver flawless service to every client on a moment’s notice.

With so many variables impacting efficiency and profitability, how can you manage the service lifecycle of your product with full confidence?

With the proper strategy, smart investment, and smart guidance you can not only keep up, but plan for the future.

The growing complexity of products in the market makes the jobs of service departments more challenging. Factors outside of a technician’s control such as unavailable parts information or delays in the supply chain can make a huge impact on profitability, client satisfaction, as well as the overall performance of your products.

New approaches to Service Lifecycle Management (SLM), along with new technology (like the internet of things) can do a great deal to streamline service operations.

Watch this on-demand webcast from PTC to learn all about industry research on the impact of the information gap at the point of service delivery and best practices to successfully meet these critical business challenges head-on.

In today’s fast-paced digital environment, the demand for accurate, consistent, and timely product information is paramount. Traditional methods of technical documentation, often reliant on manual processes and disparate tools, fall short in meeting these demands. This is where PTC Arbortext emerges as a game-changer. It offers a dynamic publishing solution that streamlines the creation, management, and delivery of technical content.

The Pitfalls of Traditional Documentation Methods

Many businesses rely on one or two technical writers to collect all required technical and digital information needed to create technical and marketing publications. Most of this effort is manual, using the tried and true method of emailing, calling, and walking down the hall to bug technical resources for information or a screen grab; over and over. Then the information is created using a one-and-done single-instance authoring software like Adobe FrameMaker, Adobe InDesign, or Microsoft Word.

This is a problem for a number of reasons, including:

- Inconsistencies and Errors: Manual data collection can lead to outdated or incorrect information permeating through various documents.

- Inefficiencies: Repetitive tasks and lack of automation slow down the documentation process, delaying product releases.

- Scalability Issues: As products become more complex, managing documentation manually becomes increasingly untenable.

Just think of everywhere incorrect information could live if an update is missed. Web sites, user manual libraries, manufacturing instructions, service instructions, printed manuals, marketing literature, and the list goes on. This can increase the risk of providing out-of-date or inaccurate information to customers, manufacturing personnel, and service technicians.

Embracing Dynamic Publishing with Arbortext

PTC Arbortext offers a comprehensive solution to these challenges by enabling dynamic publishing. This method automates and integrates the entire documentation lifecycle. Key benefits include:

- Single Source of Truth: Centralize content to ensure consistency across all documentation.

- Automated Updates: Link documentation directly to product data, allowing automatic updates when changes occur.

- Multi-Channel Delivery: Publish content across various formats and platforms without redundant efforts

Core Components of the Arbortext Suite

When arguing for Arbortext, there’s strength in overarching capabilities. However, there’s also the power and precision of its individual components. Like many other PTC product lines, Arbortext boasts a suite of several integrated tools. This robust ecosystem of tools work together to streamline structured content creation, styling, and publishing. This empowers technical teams to do more, faster, and with fewer errors. These extensions have been designed to enhance the documentation process. They include:

- Arbortext Editor: A powerful, XML-based authoring tool designed for creating structured content. It supports real-time validation, ensuring content conforms to required standards as it’s written. This not only improves accuracy but also reduces the need for post-creation corrections.

- Arbortext Styler: A stylesheet design application that lets users visually create and manage styles for multiple output formats. Publishing to PDF, HTML, or EPUB? Styler allows organizations to control formatting rules without needing to write code, greatly simplifying the publishing process.

- Arbortext Publishing Engine: The automation hub of the suite, this engine assembles, formats, and publishes content from Arbortext Editor using predefined styles and templates. It eliminates manual tasks and ensures consistent, repeatable publishing workflows across the enterprise.

Together, these tools form a tightly integrated publishing solution. This solution enables organizations to maintain consistency, scale their documentation efforts, and reduce operational risk. Whether you’re a single author or managing a global documentation team, the Arbortext suite equips you with the foundation to build and deliver content that’s smart, structured, and future-ready.

Integration with PTC Windchill for Enhanced Content Management

One of the most compelling reasons to argue for Arbortext is its seamless integration with PTC Windchill, a leading product lifecycle management (PLM) system. This connection allows organizations to manage both product data and technical content within a single, unified platform. By linking Arbortext with Windchill, companies gain tighter control over content versioning, reuse, and approval processes, which is critical in regulated industries or highly complex product environments.

Windchill serves as a single source of truth, ensuring that content creators always work with the most up-to-date product data and documentation. This reduces the risk of inconsistencies between product updates and technical materials—whether it’s a service manual, part catalog, or training content. Integration also supports granular access control, workflow automation, and traceability, helping teams stay audit-ready and in compliance.

Together, Arbortext and Windchill form a powerful digital thread that connects engineering, manufacturing, and documentation teams across the entire product lifecycle. This integration not only accelerates content creation and delivery but also reinforces data integrity and operational efficiency, making it a cornerstone argument in favor of adopting Arbortext for dynamic publishing.

Real-World Impact: Efficiency and Accuracy

When arguing for Arbortext, it’s essential to look beyond features and focus on real-world outcomes. Organizations that implement Arbortext experience measurable gains in both operational efficiency and content accuracy. By automating manual processes like formatting, layout, and publication, teams spend less time on repetitive tasks and more time on high-value content creation. This leads to faster documentation cycles and reduced time-to-market for products.

Dynamic publishing ensures that information is consistent across all deliverables, minimizing the risk of errors or outdated content reaching end users. Technical writers can generate multilingual, multi-format documents in a fraction of the time it would take using traditional tools, and updates can be made globally with just a few clicks.

Ultimately, Arbortext isn’t just about creating content—it’s about transforming how content is managed, updated, and delivered throughout the organization. These efficiency and accuracy gains drive real business value, making a strong, results-based case for integrating Arbortext into your enterprise content strategy.

Making the Case for Arbortext

In an era where information accuracy and speed are critical, arguing for Arbortext becomes a matter of strategic importance. Making the move from manual technical publications to what we just described allows tech writers to focus on optimization of publishing methods rather than data collection and integration. It helps insure overall accuracy of product data throughout the company and in the marketplace. By transitioning to dynamic publishing with PTC Arbortext, organizations can overcome the limitations of traditional documentation methods, ensuring that their technical content is accurate, consistent, and delivered efficiently across all platforms.

Most organizations recognize the importance of a ‘speedy response’ to a quality issue or a customer complaint.

In fact, faster service response time has been named as a top priority for many service lifecycle management efforts. The significant demand for manufacturers and service organizations to resolve customer issues promptly, and to quickly mitigate any product quality issues has become a challenge.

How do you overcome this challenge and implement a solution? The equation involves equipping service technicians and customer facing roles with the right information at the right time, along with aligning parts/inventory and service personnel.

For example, let’s look at a very realistic situation.

Imagine your dryer machine breaks down. You call the manufacturer and learn you have to wait three days for a service visit. Depending on your patience (and laundry needing to be done) this could be the beginning of a very unpleasant customer experience.

But what if that same manufacturer was able to pull up your model, and already knew they had visited you a year ago with a similar issue. How might your experience be impacted if they were to tell you there was a 90 percent first-time fix rate for your specific dryer and a technician would be able to show up with the specific parts needed to fix your issue?

This is the type of service that customers want and are starting to expect.

It is easy to see how putting the right information in a service technicians’ hands at the right time is so important.

Service technicians want to be able to see service information and technical service bulletins. They want to see information on the job and have access to just in time training. They have a desire for formal training, tech assist helpdesks and hotlines, and safety instructions.

So how do we enable and empower technicians to optimize service experiences and exceed customer expectations?

Here are some of the best practices that we have gathered:

- 1. Provide access to technical/service parts information when technicians need it

- 2. Make that information easy to search

- 3. Supply accurate product and configuration information including all parts and service history

- 4. Enable easy ways of ordering parts

- 5. Offer just in time training/help

‘Smart’ service management is your key to success.

Your service information needs to be managed at a network level. This ensures that all your players in the service web have access to the right information, at the moment they need it.

Adding a modern layer of accessibility to your information is a critical part of ensuring your service network can operate efficiently and effectively. This is what will help you drive positive customer experiences throughout your product lifecycle.

We offer the technology solutions and technical expertise to make real-time service information delivery a reality. Contact us to learn more about our Product Development Information Services group, PTC’s Arbortext and Service Lifecycle Management technologies, and the PLM solutions that can effectively link together your product data and service part information.